1. Transformation relationship of IMU coordinate axes

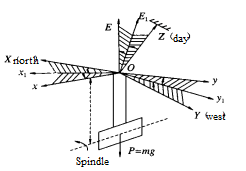

1.1IMU coordinate system

An IMU (Inertial Measurement Unit) is a sensor device that integrates an accelerometer, gyroscope, and magnetometer and is used to measure and calculate the acceleration, angular velocity, and direction of an object.

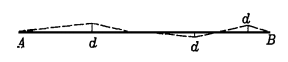

The IMU coordinate system is a reference coordinate system determined by the IMU sensor and consists of three coordinate axes: x-axis, y-axis, and z-axis.

The IMU coordinate system is usually referenced to three mutually perpendicular axes, and the specific directions vary depending on the device.

2. Definition of coordinate axes

x-axis: parallel to the IMU device and pointing to the front of the device.

y-axis: parallel to the IMU device, pointing to the right side of the device.

z-axis: parallel to the IMU device, pointing toward the top of the device.

3. Coordinate transformation relationship of IMU

There is a certain transformation relationship between the IMU coordinate system and the inertial space coordinate system.

This transformation relationship can be expressed by a rotation matrix, usually denoted as R, which is the rotation relationship between the inertial space coordinate system and the IMU coordinate system.

Assuming that the coordinates of the inertial space coordinate system are P and the coordinates of the IMU coordinate system are P’, the transformation relationship between the two can be expressed as: P’ = R * P.

This transformation relationship is determined by the placement angle of the sensor. Through calibration and precise measurement, an accurate rotation matrix can be obtained.

In addition, since IMU devices usually have errors, calibration and filtering operations are required to improve measurement accuracy and reduce errors.

4.Application

4.1Pose estimation

By monitoring the object's acceleration and angular velocity through the IMU sensor, the object's attitude can be estimated using the transformation relationship of the coordinate axes.

Posture represents the direction and rotation state of an object in three-dimensional space, and is widely used in fields such as robots, drones, and virtual reality.

4.2Sports tracking

The IMU sensor is used to measure the acceleration and angular velocity of an object, and the movement trajectory of the object can be tracked based on the transformation relationship of the coordinate axes.

Motion tracking technology is often used in sports training, posture analysis, sports simulation and other fields, and is crucial for accurately measuring and analyzing the motion status of objects.

4.3Posture control

By measuring the acceleration and angular velocity of the object through the IMU sensor, and combining the transformation relationship of the coordinate axes, the posture control of the object can be achieved.

Posture control is widely used in robots, smart wearable devices, game controllers and other fields to achieve precise motion control and interactive experience.

The transformation relationship of the IMU coordinate axis describes the rotation relationship between the inertial space coordinate system and the IMU coordinate system.

Through precise calibration and measurement, an accurate rotation matrix can be obtained, which is used to transform the coordinate system and implement application scenarios such as attitude estimation, motion tracking, and posture control.

Conclusion

The transformation relationship of the IMU coordinate axes is described by the rotation matrix.

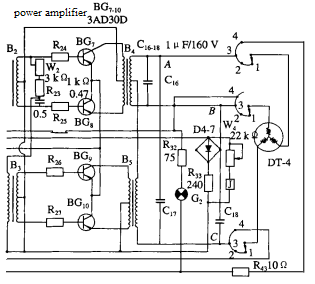

Through calibration and precise measurement, an accurate rotation matrix can be obtained, thereby realizing the conversion relationship between the inertial space coordinate system and the IMU coordinate system. The MEMS IMU independently developed by ERICCO has higher accuracy. For example, ER-MIMU-01 is a navigation level with built-in Gyro bias instability: 0.02 deg/hr, and ER-MIMU-08 is a tactical level with built-in Bias instability ≤1°/h.

In practical applications, understanding the transformation relationship of IMU coordinate axes is of great significance for tasks such as attitude estimation and motion tracking. Welcome to consult.

.jpg)

.jpg)