With the advantages of all-solid state, high performance and flexible design, fiber optic gyroscope has become the mainstream inertial gyroscope, which is widely used in many fields such as positioning and navigation, attitude control and oil well inclination measurement. Under the new situation, the new generation of inertial navigation system is developing towards miniaturization and low cost, which puts forward higher and higher requirements for the comprehensive performance of gyroscope such as volume, accuracy and cost. In recent years, hemispherical resonator gyro and MEMS gyro have developed rapidly with the advantage of small size, which has a certain impact on the fiber optic gyro market. The main challenge of traditional optical gyro volume reduction is the reduction of optical path volume. In the traditional scheme, the optical route of fiber optic gyro is composed of several discrete optical devices, each of which is realized based on different principles and processes and has independent packaging and pigtail. As a result, the device volume under the prior art is close to the reduction limit, and it is difficult to support the further reduction of the volume of fiber optic gyro. Therefore, it is urgent to explore new technical solutions to realize the effective integration of different functions of the optical path, greatly reduce the volume of the gyro optical path, improve the process compatibility, and reduce the production cost of the device.

With the development of semiconductor integrated circuit technology, integrated optical technology has gradually achieved breakthroughs, and the feature size has been continuously reduced, and it has entered the micro and nano level, which has greatly promoted the technical development of integrated optical chips, and has been applied in optical communication, optical computing, optical sensing and other fields. The integrated optical technology provides a new and promising technical solution for the miniaturization and low cost of fiber optic gyro optical path.

1 Integrated optical chip scheme design

1.1 Overall Design

The traditional optical routing light source (SLD or ASE), fiber taper coupler (referred to as "coupler"), Y branch waveguide phase modulator (referred to as "Y waveguide modulator"), detector, sensitive ring (fiber ring). Among them, the sensitive ring is the core unit of the sensitive Angle rate, and its volume size directly affects the precision of the gyro.

We propose a hybrid integrated chip, which consists of a light source component, a multifunctional component and a detection component through hybrid integration. Among them, the light source part is an independent component, which is composed of SLD chip, isolation collimation component and peripheral components such as heat sink and semiconductor cooler. The detection module consists of a detection chip and a transresistance amplifier chip. The multifunctional module is the main body of hybrid integrated chip, which is realized based on lithium niobate thin film (LNOI) chip, and mainly includes optical waveguide, mode-spot conversion, polarizer, beam splitter, mode attenuator, modulator and other on-chip structures. The beam emitted by the SLD chip is transmitted into the LNOI waveguide after isolation and collimation.

The polarizer deflects the input light, and the mode attenuator attenuates the non-working mode. After the beam splitter splits the beam and modulator modulates the phase, the output chip enters the sensitive ring and the sensitive angular rate. The light intensity is captured by the detector chip, and the generated photoelectric output flows through the transresistance amplifier chip to the demodulation circuit.

The hybrid integrated optical chip has the functions of luminescence, beam splitting, beam combining, deflection, modulation, detection, etc. It realizes the "multi-in-one" integration of non-sensitive functions of gyro optical path. Fiber optic gyroscopes depend on the sensitive Angle rate of coherent beam with high degree of polarization, and the polarization performance directly affects the precision of gyroscopes. The traditional Y-waveguide modulator itself is an integrated device, which has the functions of deflection, beam splitting, beam combining and modulation. Thanks to material modification methods such as proton exchange or titanium diffusion, Y-waveguide modulators have extremely high deflection ability. However, thin film materials need to take into account the requirements of size, integration and deflection ability, which can not be met by material modification methods. On the other hand, the mode field of thin film optical waveguide is much smaller than that of bulk material optical waveguide, resulting in changes in electrostatic field distribution and electrorefractive index parameters, and the electrode structure needs to be redesigned. Therefore, the polarizer and modulator are the core design points of the "all-in-one" chip.

1.2 Specific Design

The polarization characteristics are obtained by structural bias, and an on-chip polarizer is designed, which consists of curved waveguide and straight waveguide

Agreed. The curved waveguide can limit the difference between the transmission mode and the non-transmission mode, and achieve the effect of mode bias. The transmission loss of the transmission mode is reduced by setting the offset.

The transmission characteristics of optical waveguide are mainly affected by scattering loss, mode leakage, radiation loss and mode mismatch loss. Theoretically, the scattering loss and mode leakage of small curved waveguides are small, which are mainly limited by the late process. However, the radiation loss of curved waveguides is inherent and has different effects on different modes. The transmission characteristics of the curved waveguide are mainly affected by the mode mismatch loss, and there is mode overlap at the junction of the straight waveguide and the curved waveguide, resulting in a sharp increase in mode scattering. When the light wave is transmitted into the polarized waveguide, due to the existence of curvature, the effective refractive index of the light wave mode is different in the vertical direction and the parallel direction, and the mode restriction is different, which results in different attenuation effects for TE and TM modes.

Therefore, it is necessary to design the bending waveguide parameters to achieve the deflection performance. Among them, bending radius is the key parameter of bending waveguide. The transmission loss under different bending radius and the loss comparison between different modes are calculated by FDTD eigenmode solver. The calculated results show that the loss of the waveguide decreases with the increase of the radius at small bending radius. On this basis, the relationship between polarization property (ratio of TE mode to TM mode) and bending radius is calculated, and the polarization property is inversely proportional to bending radius. The determination of the bending radius of the on-chip polarizer should consider the theoretical calculation, the simulation results, the technological capability and the actual demand.

The finite difference Time domain (FDTD) is used to simulate the transmitted light field of the on-chip polarizer. The TE mode can pass through the waveguide structure with low loss, while the TM mode can produce obvious mode attenuation, so as to obtain polarized light with high extinction ratio. By increasing the number of cascaded waveguides, the extinction ratio of the polarization-extinction ratio can be further improved, and better than -35dB polarization extinction ratio performance can be obtained on the micron scale. At the same time, the structure of the waveguide on chip is simple, and it is easy to realize the low-cost fabrication of the device.

2 Integrated optical chip performance verification

The LNOI main chip of the integrated optical chip is an unsliced sample engraved with multiple chip structures, and the size of a single LNOI main chip is 11mm×3mm. The performance test of integrated optical chip mainly includes the measurement of spectral ratio, polarization extinction ratio and half-wave voltage.

Based on the integrated optical chip, a gyroscope prototype is built, and the performance test of the integrated optical chip is carried out. Static zero bias performance of a gyro prototype based on integrated optical chip in a non-vibration isolated foundation at room temperature. set-based

The gyroscope formed into optical chip has a long time drift in the start-up segment, which is mainly caused by the start-up characteristic of light source and the large loss of optical link. In the 90min test, the zero bias stability of the gyroscope is 0.17°/h (10s). Compared with the gyroscope based on traditional discrete devices, the zero bias stability index deteriorates by an order of magnitude, indicating that the integrated optical chip needs to be further optimized. Main optimization directions: improve the polarization extinction ratio of the chip, improve the luminous power of the light-emitting chip, improve the end-coupling efficiency of the chip, and reduce the overall loss of the integrated chip.

3 Summary

We propose an integrated optical chip based on LNOI, which can realize the integration of non-sensitive functions such as luminescence, beam splitting, beam combining, deflection, modulation and detection. The zero bias stability of the gyro prototype based on the integrated optical chip is 0.17°/h. Compared with the traditional discrete devices, the performance of the chip still has a certain gap, which needs to be further optimized and improved. We preliminarily explore the feasibility of fully integrated optical path functions except ring, which can maximize the application value of integrated optical chip in gyro, and meet the development needs of miniaturization and low cost of fiber optic gyro.

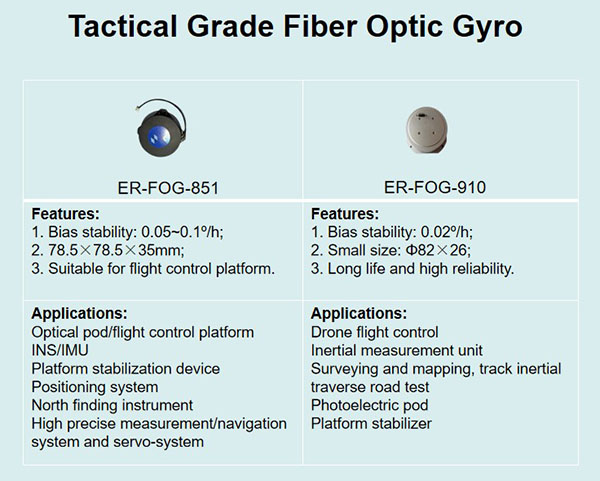

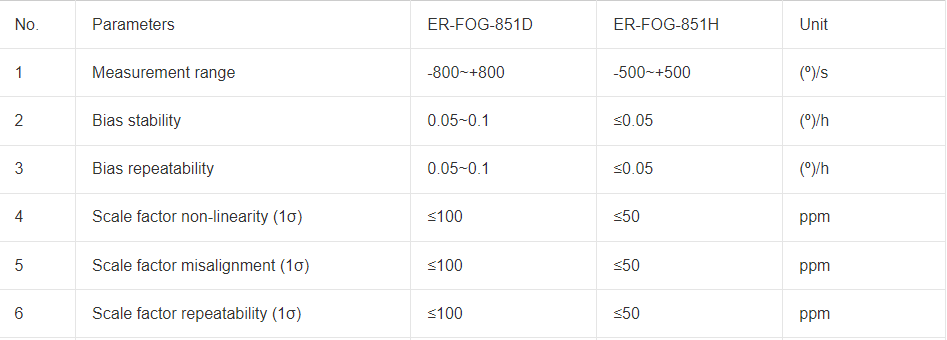

Ericco's ER-FOG-851, ER-FOG-910 small size, low power consumption, of course, the cost is also low, the application field is particularly wide, such as IMU, INS, north finding system, etc., I believe you must want to know their specific technical parameters, please feel free to contact us.

.jpg)

.jpg)