When it comes to the use of tilt sensors to monitor angles, people's first reaction may feel very strange, in fact, we often use the mobile phone has a similar function, it is easy to search the relevant app in the mobile app store, and it is also very convenient to use, although there may be no one in the work really use the mobile phone as a measurement tool. But we can fully see that the measurement of the tilt Angle has been very easy.

At present, the inclination sensors used in many fields are basically based on MEMS (Micro-electro Mechanical System for short, Chinese name micro-electro-mechanical system) tilt sensors, around 1960, the United States took the lead in studying MEMS technology, Then France, Germany, Switzerland, Japan and other countries also began to pay attention to MEMS research work, China's MEMS research began in 1989, to 1999, China's domestic MEMS research and development units have reached more than 50, the level of scientific research can also be placed in the international top ten. As of 2010, there are about 600 units engaged in the research and production of MEMS in the world.

MEMS is an independent intelligent system, which integrates micro sensor, signal processing, actuator, interface circuit, control circuit, communication and power supply in one. It has the advantages of small size, low power consumption, light weight, strong durability, high stability, low price and easy mass production. It can be seen that MEMS refers to a system that is integrated by multiple devices. The current research on MEMS technology mainly includes: micro-mechanical pressure sensor, micro-gas sensor, micro-acceleration sensor, micro-flow sensor, micro-mechanical gyroscope, micro-mechanical temperature sensor and other micro-mechanical sensors.

Mems-based sensors have many uses, measuring tilt angle is just one of them, using acceleration sensors, such as gas flow measurement, temperature measurement, pressure measurement, and so on.

The application of MEMS technology to monitor the tilt angle of large outdoor advertisements is not a blind decision.

1. Monitoring methods for large-scale outdoor advertising

At present, there are four main monitoring methods for large-scale outdoor advertising:

(1) Camera monitoring

Due to the large outdoor advertising area is large, very eye-catching, mostly erected in bustling areas, highways and overpasses near, these geographical locations are also key jurisdiction areas of the city, therefore, these areas are basically covered by urban surveillance cameras, administrators can view large advertising and its surrounding situation through real-time monitoring. Although this monitoring method seems to have the characteristics of real-time, but it is difficult to achieve in practical applications, the monitor can not always stare at the surveillance video, and when the visibility is low, the effect of the surveillance video will be reduced a lot, affecting the observation of the monitor, therefore, the use of this method to monitor large-scale advertising is not ideal.

(2) Regular manual inspection

Surveyors field measurement is the most traditional monitoring method, the longest application time, the monitoring process is relatively mature,

This method is mainly used by inspectors to measure large advertisements using steel tape, optical theodolite, portable ultrasonic flaw detector, weld gauge, rebound meter and other equipment. Due to the support of high-precision data, this method has high credibility, but in order to achieve rapid and comprehensive monitoring of all large advertisements, not only need multiple sets of monitoring equipment. It also needs to use more manpower and material resources, which is very inconvenient, and this method is mainly preventive, which cannot achieve real-time understanding of large-scale advertising conditions, so this method is not ideal.

(3) Monitoring based on radio frequency technology

The technology is a non-contact automatic identification technology that emerged around 1990, which carries out non-contact two-way data transmission between the base station and the radio frequency card to achieve the purpose of identifying the target and data transmission. This method mainly uses 2.4GHz active radio frequency electronic tag to record the attribute information and location information of large advertisements. The electronic tag can sense the displacement, and a receiving base station is required to receive, process and transmit the data sent by the electronic tag. The technology is widely used in many fields such as small advertising management, highway ETC express lanes, logistics, retail and so on.

Although this method can obtain the position data of large advertisements in real time, it is not its strong point in monitoring the tilt Angle. This method can make up for the shortcomings of the above two methods, but the final result can not measure the tilt of large advertisements

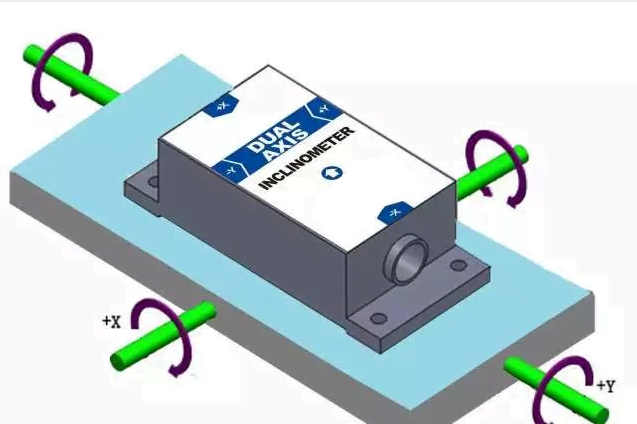

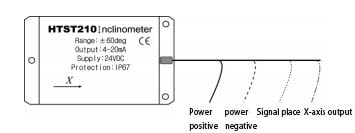

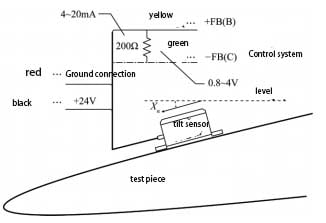

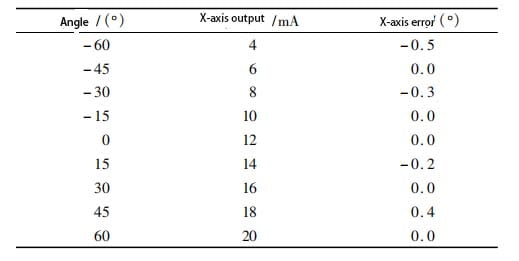

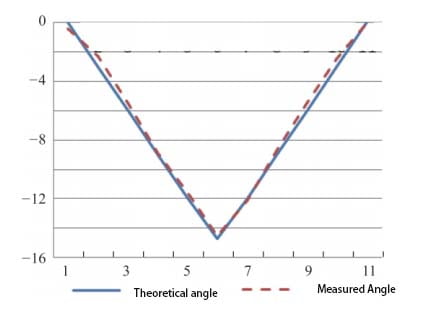

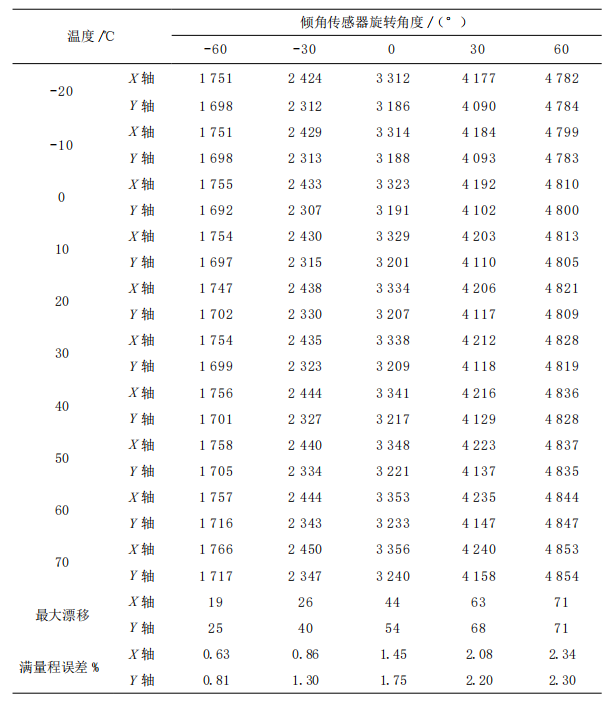

(4) Sensor-based inclination monitoring

Tilt sensor is often used to measure the change in inclination relative to the horizontal plane, it is based on Newton's second law as a theory, according to the basic principles of physics, in a system, the speed can not be measured, but can measure its acceleration, under the condition of the initial speed is known, you can use the integral method to calculate the line speed, and then calculate the linear displacement. So it's an acceleration sensor that uses the principle of inertia. The tilt sensor is fixed on the back of a large advertisement, and the single chip microcomputer is used as the central controller to integrate the monitored angle data, monitoring time, monitoring site number and other information, and then through the General Packet Radio Service (GPRS), The wireless communication module will send out the packaged data, and the data will be analyzed and processed by the monitoring personnel, and this equipment is powered by solar energy + battery, making the equipment more independent and easier to manage. This method can understand the angle information of large advertisements in real time. In the case of investing very little manpower and material resources, you can fully understand the situation of each large advertisement, and the data credibility is high, so this way is more ideal.

2 Summary

In summary, after a more detailed analysis of various monitoring methods, it is not difficult to see that the method based on tilt sensors is the best to use this method to monitor the tilt of large-scale outdoor advertising. Ericco has various precision and types of tilt sensors, like ER-TS-3160VO, ER-TS-12200-Modbus, widely used in Bridges, DAMS, building monitoring and other fields, if you want to buy or want more technical data of tilt sensor, you can contact us at any time.

.jpg)