Introduction

Quartz accelerometers are widely used in various applications, ranging from automotive and aerospace industries to consumer electronics and navigation systems. These devices play a crucial role in measuring acceleration, tilt, and vibration, providing essential data for motion sensing and control. In this article, we will explore the working principle of quartz accelerometers, delving into their internal mechanisms and explaining how they accurately detect and measure acceleration.

Piezoelectric Effect

At the heart of a quartz accelerometer is the piezoelectric effect. Quartz crystals, when subjected to mechanical stress or pressure, generate an electrical charge. This phenomenon occurs due to the unique atomic structure of quartz, which exhibits piezoelectric properties. When the crystal is deformed or compressed, positive and negative charges are separated, creating an electric potential across the crystal.

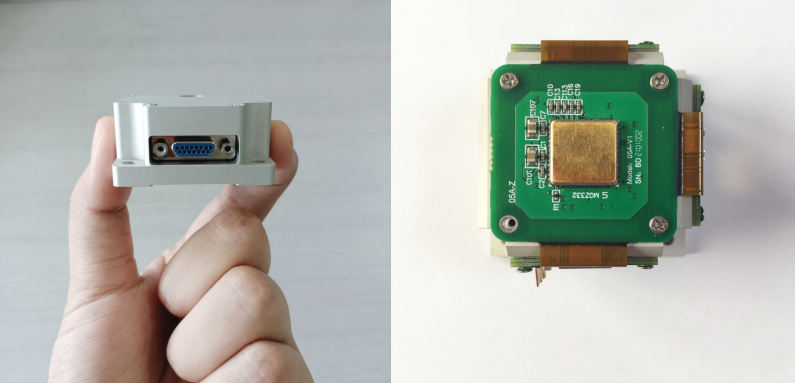

Sensor Structure

A quartz accelerometer consists of a mass attached to a quartz crystal. The mass is typically suspended by a spring or other compliant structure, allowing it to move in response to acceleration. As the accelerometer experiences acceleration, the mass moves relative to the crystal, exerting mechanical stress on it.

Oscillation and Resonance Frequency

The quartz crystal in the accelerometer is carefully cut and shaped to have a specific resonant frequency. When an alternating voltage is applied to the crystal, it vibrates or oscillates at its resonant frequency. This resonant frequency is determined by the dimensions and material properties of the crystal.

Detection and Measurement of Acceleration

When acceleration is applied to the accelerometer, the mass attached to the crystal experiences a displacement, resulting in a change in the mechanical stress on the crystal. This change in stress alters the resonant frequency of the crystal. The accelerometer measures this frequency shift, which is directly proportional to the applied acceleration.

Electronic Circuitry

The electronic circuitry in the quartz accelerometer is responsible for applying the alternating voltage to the crystal, detecting the resonant frequency shift, and converting it into an electrical signal. The signal is then processed and amplified to provide a measurement of the applied acceleration.

Calibration and Compensation

Quartz accelerometers undergo calibration to ensure accurate and precise measurements. Calibration involves subjecting the accelerometer to known acceleration values and adjusting the circuitry to match the output with the expected values. Additionally, compensation techniques are employed to minimize errors due to temperature changes, cross-axis sensitivity, and other environmental factors.

Frequently Asked Questions (FAQs)

Q: Are quartz accelerometers more accurate than other types of accelerometers?

A: Quartz accelerometers are known for their high accuracy and stability. Their precise resonant frequency measurement allows for accurate determination of acceleration. However, other types of accelerometers, such as MEMS (Microelectromechanical Systems) accelerometers, have gained popularity due to their smaller size, lower cost, and suitability for certain applications.

Q: What is the frequency range of quartz accelerometers?

A: The frequency range of quartz accelerometers can vary depending on the specific model and application. Some quartz accelerometers are designed for low-frequency applications, while others are capable of measuring higher-frequency accelerations. The frequency range is typically specified by the manufacturer and should be considered when selecting an accelerometer for a particular application.

Q: Can quartz accelerometers measure tilt or inclination?

A: Yes, quartz accelerometers can measure both linear acceleration and tilt or inclination. By analyzing the output signals from multiple axes, quartz accelerometers can determine the orientation and tilt angle of an object relative to the gravitational field.

Q: What are the advantages of quartz accelerometers over other types of accelerometers?

A: Quartz accelerometers offer several advantages, including high accuracy, stability, and robustness. They are less susceptible to temperature variations and exhibit low cross-axis sensitivity. Quartz accelerometers also have a wide dynamic range, making them suitable for a broad range of applications.

Q: How are quartz accelerometers used in automotive applications?

A: In automotive applications, quartz accelerometers are utilized for various purposes, such as vehicle stability control, airbag deployment, and suspension control. They provide critical information about the vehicle's acceleration, orientation, and vibrations, enabling precise and responsive control systems.

Conclusion

Quartz accelerometers rely on the piezoelectric effect and the resonant frequency of quartz crystals to accurately measure acceleration. By detecting the frequency shift caused by mechanical stress on the crystal, these accelerometers provide valuable data for motion sensing and control. Their high accuracy, stability, and versatility make them indispensable in numerous applications, from consumer electronics to industrial and automotive systems. Understanding the working principle of High Performance quartz accelerometers helps in appreciating their capabilities and selecting the appropriate sensor for specific measurement needs.

.jpg)