North-seeking methods include inertial instrument north-seeking method, astronomical observation method, geodetic method, magnetic north-seeking method, satellite positioning method, reference object method and other methods. However, only the north-seeking instrument developed using the principle of inertia can independently complete the north-seeking task without being disturbed by natural conditions or environment, and has the characteristics of long continuous working time and high accuracy.

The north seeker mainly determines the true north value of the attached carrier by measuring the angular velocity of the earth’s rotation, without being interfered or affected by external magnetic fields or other environments. There are many types of inertial north seekers on the market, so it is particularly important to choose a north seeker. This article will introduce in detail how to choose a suitable north seeker through its core sensor, application environment, size, weight and accuracy.

Selection Factors for North Finder

Core Sensor

The core sensor plays a decisive role in the north seeker and greatly affects the north seeker accuracy. Therefore, the core sensor is crucial when choosing a north seeker. There are three main core sensors currently used in north seekers: ring laser gyroscopes (RLG). Gyroscope technology also includes fiber optic gyroscopes (FOG) and microelectromechanical systems (MEMS) gyroscopes, which can be selected according to the application field and requirements. Choose precision small, compact, lightweight and radiation resistant, the RLG is compact and self-contained and does not create friction, which can affect accuracy and increase “drift” over time. In fact, compared to mechanical gyroscopes that can drift 0.1-0.01 degrees per hour, the RLG drifts about 0.0035 degrees, making it suitable for low-cost vehicle positioning and north-finding applications. However, the ring laser gyroscope (RLG) has dominated the inertial navigation market since its first introduction in 1963. Its dominance is gradually being challenged by technological improvements in fiber optic gyroscopes (FOG), which are also slowly occupying RLG in the inertial navigation market.

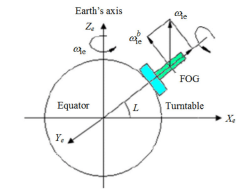

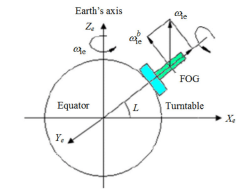

Fiber Optic Gyroscopes (FOG) have higher inertial performance and lower bias than RLG gyroscopes, making them the solution of choice for high-precision applications such as GNSS rejection environments or antenna pointing. A fiber optic gyroscope is a solid-state device that does not use a dither mechanism, which means it does not produce any acoustic vibrations, making it more durable and reliable than an RLG. In addition, fiber optic gyroscope applications can be expanded by changing the length and diameter of the fiber coil.

MEMS technology has made great progress in recent years. MEMS rate gyroscopes measure the earth’s rotation angular velocity to calculate the azimuth angle, collect the output of the gyroscope at different azimuth angles, and perform signal processing to calculate the azimuth angle of the device. MEMS sensors achieve higher accuracy, improved error characteristics, and better sensitivity, significantly improving overall MEMS performance. While other companies produce millions of MEMS for commercial and consumer products, Ericco focuses on high-performance systems typically used in aerospace, defense and transportation applications. For example, ER-MNS-05 is fully temperature compensated and has high precision and sensitivity characteristics, which greatly improves work efficiency.

Therefore, when choosing a north seeker, special attention should be paid to its core sensor. Sensor accuracy can improve the overall performance of the north seeker. If the requirement for north seeking accuracy is slightly higher: around 0.1°, 0.2°~0.02°, you can choose an optical fiber sensor (FOG). If you require ultra-high accuracy and there are no strict requirements on volume, you can choose a laser sensor (RLG) as the seeker. The accuracy can reach about 0.01°~0.005°. You can choose a north-seeking instrument according to your own requirements for north-seeking accuracy, which can achieve twice the result with half the effort.

Size and Weight

Because the application fields of north seekers are different, the working spaces are also different, in some complex working areas such as drilling rigs, mines, tunnel boring machines, etc. There are two main types of north seekers: MEMS and FOG. The MEMS north seeker is small and lightweight. MEMS also consume less power than FOG, providing longer mission times for fuel-constrained vehicles. If you have strict requirements on size, MEMS is the most recommended. For example, ER-MNS-06 is the smallest north finder in the world, only 44.84×38.88×21.39mm, weight ≤60g, and accuracy of 0.25°-1. If the weight and size requirements are not strict, but accuracy is required, a laser sensor (RLG) can be selected as the north finder. If there are some requirements for size and accuracy, it is recommended to choose an optical fiber sensor (FOG) as the north finder. For example: ER-FNS-03, with dimensions of 200×100×90mm/210×125×105mm, and a weight of 2.0Kg. It has the same accuracy as the mems north finder and is small in size.

North Seeking Accuracy

Another north-finding capability unique to FOG, even in highly magnetic environments. In contrast to MEMS technology, which relies on magnetometers for accurate heading, FOG accurately measures the Earth’s angular rate of rotation even when it’s in motion and can accurately determine north direction within minutes. This is a particularly welcome feature for subsea applications that cannot rely on any GNSS signal for long periods of time. For example, the ER-FNS-03, a low-cost 3-axis FOG north seeker, is the leader among FOG north seekers.

If the requirements for north seeking accuracy are particularly high, one time Sigma, and an accuracy of 0.001 or above, a laser sensor will generally be selected as the north seeker. At around 0.01°~0.5°, an optical fiber sensor can be selected as the north seeker, while the mems north seeker generally The north accuracy is around 0.5°~1°, 2°. Once the important accuracy is determined, everyone will be able to purchase a high-quality north finder, which will also reduce errors for practical applications.

Application Areas

Gyroscopic orth-finding systems are widely used in various fields of the national economy and military. When using gyroscopic north-seeking systems to obtain azimuth information, there are many different observation methods and operating procedures based on different industry characteristics and constraints. The transmission and aiming of azimuth are the most commonly used and basic links. Many typical applications of gyro north-finding systems require the application of this technology.

Measurement of Centerline of Tunnel Project

During the construction and construction processes of mining, transportation and other industries, tunnel shield excavation is carried out underground, and the acquisition of northbound information is the basis for the smooth progress of the project. In excavation projects such as tunnels, the centerline measurement in the pit generally uses long-distance wires that are difficult to ensure accuracy. Especially when carrying out shield excavation, it is necessary to have high angle measurement accuracy and station shifting accuracy starting from the short reference center line of the pit. During the measurement, corresponding inspections on the ground and underground must be carried out frequently to ensure the accuracy of the measurement. However, in dense urban areas, it is difficult to ensure measurement accuracy because it is impossible to carry out too many inspection operations. If you use a gyro theodolite, you can get an absolutely high-precision azimuth reference, and it can reduce the cost-intensive inspection work (with the least number of inspection points), and it is a very efficient centerline measurement method.

Targeting of Weapon Systems in the Military

The gyroscopic north-seeking system can play a huge role in military geodesic operations, that is, to provide reference quasi-shooting directions for weapon systems such as artillery and missiles, and to conduct measurements to obtain northbound signals. Conventional operation methods make geodesic protection in mind. It is basic, but the effective use of the weapon’s power has been tested. For example, in the artillery unit’s geodesic operations, to a certain extent, whether it is controlled measurement or continuous measurement of artillery battle formations, the methods to obtain higher accuracy include the following: retrieving or calculating the orientation based on the result data, inducing the orientation, Astronomical orientation determination has great limitations in practical operations, which affects the speed and accuracy of geodetic operations to a certain extent. The introduction of the gyro north-finding system has solved the problem of all-weather accurate position acquisition, greatly improved the operating methods, facilitated the comprehensive implementation of the operating methods, and made fast and accurate geodetic support a reality.

Many Equipment in the Defense Industry

A large number of orientation requirements, for example: inertial navigation equipment needs to establish an indoor north direction reference, the zero direction or axis of the inertial navigation test turntable needs to point in a certain direction; the antennas of the radio frequency simulation laboratory (up to several hundred Even thousands) need to be distributed on the spherical array and required to point to the center of the sphere. Some require the true north direction. The zero direction of the spherical center turntable needs to be aligned with the zero position of the spherical array; inertial navigation test products need to determine the true north direction; inertial navigation test products need to determine the true north direction. The pilot test turntable needs to detect the accuracy of the rotation. With the development of my country’s national defense, aviation and manned space industry, these fields and disciplines are in urgent need of high-precision directional measurement technology support.

Azimuth Datum and Azimuth Datum Device

In situations where north direction information needs to be frequently used for reference, it is often necessary to save the azimuth information and establish various azimuth datums, such as the calibration azimuth of various instruments and equipment, the azimuth of landmarks, the north direction of the turntable installation, etc. The north direction of these datums Errors will directly affect the quality of work, such as inertial instrument testing accuracy, engineering construction azimuth accuracy, etc. The accuracy is often required to be as high as arcsecond level or above. In application scenarios such as dynamic initial calibration, static initial calibration, and direction control of radars, antennas, vehicles, etc., the fiber optic gyro north seeker ER-FNS-02 is a perfect match for these working scenarios and has the characteristics of strong stability and high reliability. , the accuracy reaches (0.02°-0.1°), used for high-precision initial alignment and direction control solutions, providing a lot of convenience for work. Accuracy can improve relatively over time. The north-finding time of a gyro-theodolite generally takes about 5 to 20 minutes, and the accuracy can reach 10”.

In the measurement application of the centerline of tunnel projects, the north-seeking accuracy is extremely high, generally around 0.005°. High-precision sensors must be selected as the north-finding instrument, such as RLG laser sensors as the north-seeking instrument. The aiming of weapon systems in the military generally uses sensors of about 0.5°~0.02°. The requirements for azimuth reference and azimuth reference devices are also relatively high. For calibration devices, sensors of 0.001° are generally used as north seekers.The application scope of the north seeker is quite wide. It plays an important role in modern national defense construction and national economic construction. If the north seeker does not meet your own requirements, you should choose it according to your own application needs and the parameters of the north seeker. Select or customize to achieve coordination between north-finding accuracy and north-seeking speed.

If you are interested in this north finder, you can leave me a message or send a quote and I will send you the price and technical description.

contact us:

Email: info@ericcointernational.com

WeChat: 13992884879

WhatsApp: 13630231561

.jpg)