The accelerometer uses high quality quartz crystals to achieve high precision acceleration measurement with extremely high reliability and stability. Its special flexible construction enables it to adapt to high acceleration applications under various environmental conditions, such as high temperature, high pressure and high vibration environments.

Accelerometers are an important part of aircraft, which can help control the attitude and stability of aircraft, helicopters, drones, etc. Accelerometer technology can detect the acceleration of the position to find out whether other aircraft are running over the aircraft, so that the aircraft can correct the deviation in time and maintain stability.

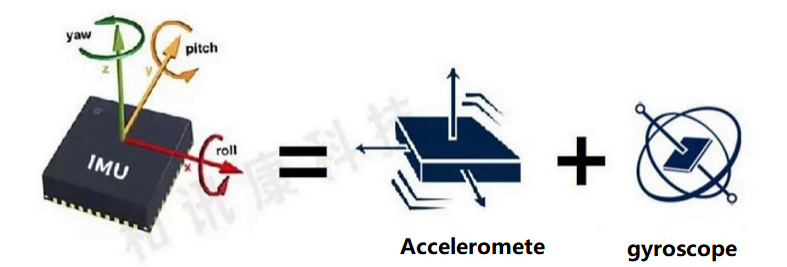

The attitude indication system on the aircraft mainly refers to the instrument system that accurately measures and indicates the attitude of the aircraft, which provides the pitch Angle, roll Angle and yaw Angle for the pilot and other on-board electronic products (such as flight guidance system, automatic flight control system and radar, etc.). The traditional attitude indication system is mainly composed of horizon instrument aircraft, turning instrument and sidering-slip instrument, with large size, cumbersome structure and weak accuracy. The digital attitude indication system widely used today uses high-precision gyro and accelerometer, with greatly improved accuracy. However, because the traditional high-precision gyro has weak overload carrying capacity, large size and expensive price, its application scenario is greatly limited. The Ericco accelerometer ER-QA-01A, specially designed for aviation applications, is not only small in size but also has a bias repeatability of 10μg, a proportional coefficient repeatability of 10 PPM, and a Class II nonlinear repeatability of 10μg/g². The high precision navigation MEMS gyroscope ER-MG2-300/400 is capable of meeting the measurement range of ±400°/s, 0.05°°/hr bias instability and 0.025°/√hr Angle random walk, in addition to the strict requirements for accuracy and carrier space size in the aviation field, compared to other products of the same type. Or other advantages.

The principle of the angular accelerometer is similar to that of an accelerometer. Its outer box is mounted on a rotating object. Due to the angular acceleration, a tangential dynamic load is generated on the reference mass, and a signal proportional to the magnitude of the tangential acceleration or the angular acceleration can be output. With different measured moving objects and measurement requirements, accelerometers have various principles and implementations. For example, on the aircraft, there are gyro accelerometers designed according to the gyro principle.

Measure the acceleration of the carrier line. An accelerometer that measures aircraft overload is one of the first aircraft instruments to be applied. Accelerometers are also commonly used on aircraft to monitor engine failure and fatigue damage of aircraft structures. Accelerometers are important tools for investigating flutter and fatigue life of aircraft in flight tests of various types of aircraft. In a flight control system, an accelerometer is an important dynamic characteristic correction element. In inertial navigation systems, a high-precision accelerometer is one of the most basic sensitive components. The accelerometers used in different occasions vary greatly in performance. A high-precision inertial navigation system requires the resolution of the accelerometer to be as high as 0.001 g, but the range is not large; an accelerometer for measuring an aircraft overload may require a 10 g range, and the accuracy The demand is not high.

Email : info@ericcointernational.com

Whats app:13992884879

.jpg)