Ericcogyro is a leader supplier of Inertial Sensor products North Finder,North seeking system,DTG,FOG,MEMS Gyroscope,Accelerometer,IMU,INS,electronic compass, our inertial sensor are sold worldwide and get the good feedback from our clients .

Thursday, January 25, 2024

Application of Improved Wavelet De-noising Method in MEMS-IMU Signals

contact me :

Email: info@ericcointernational.com

WhatsApp: +8613992884879

Wednesday, January 24, 2024

Tilt Sensor Automatic Calibration System

Full text: https://www.ericcointernational.com/application/tilt-sensor-automatic-calibration-system.html

1. Tilt sensor calibration method

Tilt sensor is widely used in the field of engineering measurement, and its measurement accuracy is often related to the evaluation of the deformation of structures, which is of great significance to the construction quality control and safety production management of construction engineering site. The manual two-point calibration method is commonly used to calibrate the inclinometer sensor, which describes the relationship between the output voltage and the Angle through a straight line, and is usually only suitable for the inclination sensor with low accuracy requirements. If the sensor has relatively high accuracy requirements, it is necessary to use a higher precision inclination chip and calibration method. Multi-point calibration is an effective calibration method to improve the accuracy of sensors, but in the case of a large number of fixed points using manual trigger, reading and calculation calibration method, not only low efficiency, and by human factors interference, is not conducive to the large-scale production of sensors. By designing an automatic calibration system for tilt sensor based on programmable electric Angle station, we realize the automatic change of Angle, reading and result output in the calibration process of inclinometer sensor, improve the calibration efficiency and sensor accuracy, and reduce the dependence of the calibration process on the technical level and experience of the operator.Application of Improved Wavelet De-noising Method in MEMS-IMU Signals

https://www.ericcointernational.com/application/application-of-improved-wavelet-de-noising-method-in-mems-imu-signals.html

IMU is an inertial measurement unit. Nowadays, MEMS IMU is widely chosen by consumers due to its advantages such as small size, high efficiency, and low cost. Therefore, the accuracy requirements for MEMS IMU will be relatively high. The main factors that can affect the accuracy of MEMS-IMU include Deterministic errors and random errors. Deterministic errors can be eliminated through calibration techniques; for random errors, Kalman filtering (KF) is usually used. However, KF requires a certain filtering model. The random error of MEMS-IMU is weakly nonlinear, non-stationary, and slowly time-varying, and is easily affected by uncertain factors such as the external environment. In this case, it is difficult to establish an accurate error model. At this time, using KF to deal with random errors will lead to low filtering accuracy and even filtering divergence.

Wavelet transform is a signal analysis method developed in the 1980s. Wavelet analysis is suitable for non-stationary signals, it can analyze local features, and can effectively reduce spike noise in non-stationary white noise. In addition, wavelet analysis does not require the establishment of a random error model, so it is very suitable for noise reduction processing of MEMS-IMU signals. The commonly used method for wavelet denoising is the wavelet threshold method, which can be traditionally divided into hard threshold method and soft threshold method. The hard threshold method can preserve the mutation signal well, but the hard threshold function is discontinuous at the threshold λj, which causes some oscillations when the signal is reconstructed using the estimated wavelet coefficients. The soft threshold method is continuous at the threshold λj, but there is a constant deviation λj between the estimated wavelet coefficients and those of the original signal, which results in blurred edges of the reconstructed signal and affects the accuracy of the reconstructed signal. If the improved threshold function has good continuity at the threshold λj, when the wavelet coefficients tend to infinity, the difference between the estimated wavelet coefficients and the original signal tends to zero. The original signal can be better preserved. However, the coefficient β in the improvement function is uncertain. To handle different signals, a large number of different betas need to be tested to adapt to the current signal, which results in poor flexibility.

In response to the above problems, this paper constructs a new wavelet threshold function without uncertainty coefficient, which makes up for the shortcomings of traditional soft and hard threshold functions and has better flexibility. It also shows that the improved wavelet threshold function can effectively reduce the noise of MEMS-IMU. This article will describe traditional wavelet threshold denoising, improved wavelet threshold function, and experimental results and analysis.

1.Traditional wavelet threshold denoising

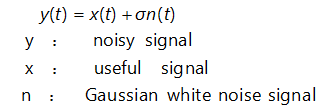

The basic idea of wavelet threshold denoising was first proposed by Dohono of Stanford University. The algorithm is simple, requires little calculation, and is especially suitable for Gaussian white noise. The basic idea is as follows. Assume that the time signal sequence is:

The noise signal is decomposed after wavelet transformation, and the wavelet coefficient value of the useful signal is greater than the wavelet coefficient value of the noise signal. Once appropriate thresholds are selected at different scales, wavelet coefficient values smaller than the predetermined threshold are directly reset to zero, while wavelet coefficient values larger than the predetermined threshold are retained or reduced. Then, the processed wavelet coefficient values are used to reconstruct the wavelet signal to suppress the noise. The main step of the wavelet denoising method is the process.

(1)Perform wavelet transform on the noise signal y. The basic formula is:

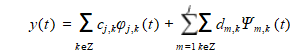

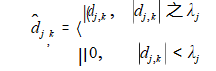

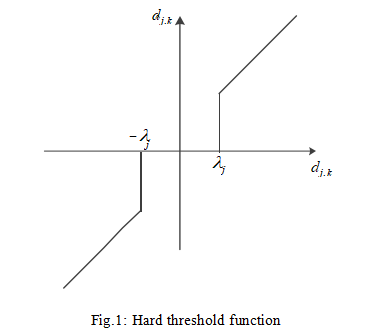

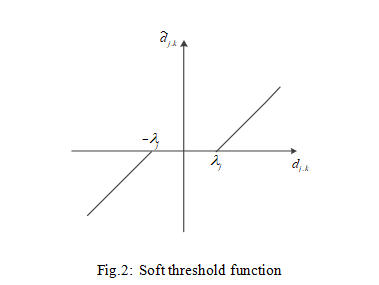

(2) Perform threshold processing on the wavelet coefficient d. Commonly used threshold functions include hard threshold functions and soft threshold functions. Perform threshold processing on wavelet coefficients. Commonly used threshold functions include hard threshold function and soft threshold function.

The hard threshold function can be described as:

The soft threshold function can be described as:

The function graphs of hard and soft threshold functions are shown in Figure 1 and Figure 2 respectively.

(3)Use the threshold-processed wavelet coefficient d to perform inverse wavelet transformation on the signal according to equation (2) to complete the wavelet reconstruction of the signal and obtain the denoised signal. Although the commonly used threshold function is simple and requires less calculation, it also has its shortcomings. The hard threshold function is discontinuous at A, so oscillations occur when the signal is reconstructed using the processed wavelet coefficients. Although the soft threshold function solves the discontinuity problem in hard threshold, there is always a constant deviation that affects the reconstruction accuracy.

2.Improved wavelet threshold function

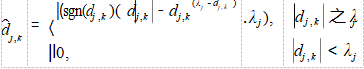

In view of the shortcomings of the above soft and hard threshold functions, this paper constructs a new wavelet function. The improved wavelet threshold function can be recorded as:

The improved wavelet function image is shown in Figure 3.

As can be seen from Figure 3, the improved wavelet function is continuous at the threshold, which makes the denoised signal after wavelet reconstruction have better smoothness and can retain the characteristics of the original signal. In addition, there is no uncertainty coefficient in equation (5), which is more flexible for denoising.

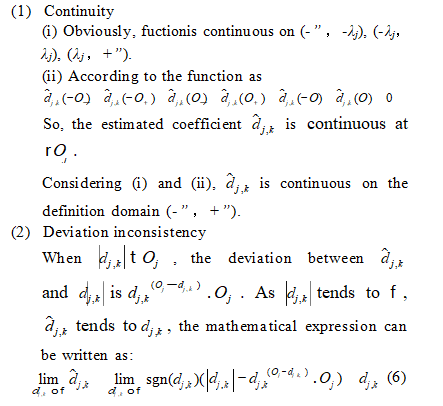

The continuity and deviation inconsistencies of the improved wavelet threshold function are proved as follows:

3.Experimental results and analysis

Through the MEMS-IMU measured data experiment, the denoising effect of the improved method on the MEMS-IMU output signal was verified.

The experimental conditions are as follows:

Set the MEMS-IMU to static and the gyroscope constant bias to 0.2. /h, gyroscope random white noise set to 10. /h standard deviation (SD). The accelerometer constant bias is set to 5u 10 to 3 g, and the accelerometer random white noise is set to 10 to 2 g SD. The output frequency is 10 Hz and the experimental time is 60 s.

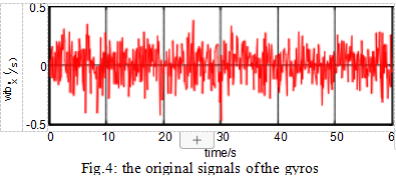

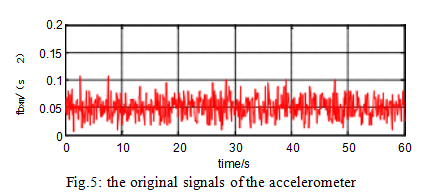

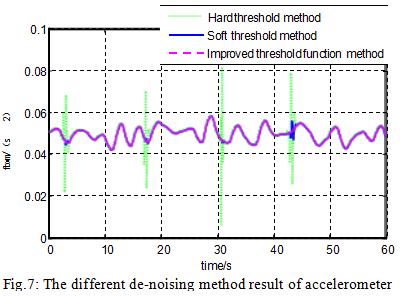

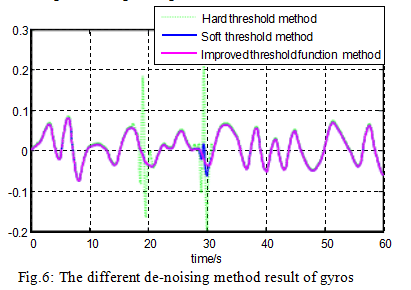

The raw signals from the gyroscope and accelerometer are shown in Figures 4 and 5. The denoising results of different methods for gyroscopes and accelerometers are shown in Figures 6 and 7.

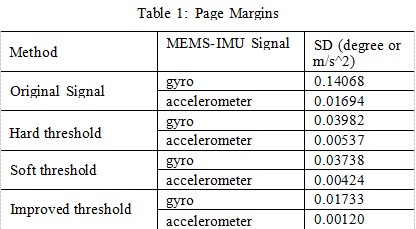

Statistically rank the SD and denoised signals of the original signal for each method. The results are shown in the table below.

It can be seen from Figure 4 to Figure 7 and Table 1 that for the hard threshold denoising method, the reconstructed signal is easy to oscillate. For the soft threshold denoising method, the reconstructed signal accuracy is not high and the signal is not smooth. The improved wavelet threshold denoising method, the reconstructed signal is smooth, and the SD is smaller than the soft and hard thresholds, which fully demonstrates that the improved method has better denoising effect than the soft and hard thresholds.

Conclusion

The wavelet threshold function constructed in this paper overcomes the oscillation problem of the reconstructed signal caused by the discontinuity of the hard threshold function, and also solves the constant deviation problem of the soft threshold function. The noise in the signal is reduced and random errors in the MEMS-IMU signal can be effectively suppressed. So the company that is better at dealing with the signal error of MEMS IMU is ERICCO INERTIAL SYSTEM. As a company that develops inertial navigation products, ERICCO has independently developed MEMS IMU for many years, which can minimize the signal interference of MEMS IMU and improve the signal quality. Optimized for denoising. For example, ER-MIMU-01 and ER-MIMU-02, the accuracy of the gyroscope and accelerometer is relatively high compared to other companies. These two products are independently developed by ERICCO and are considered hot-selling products. If you want to buy MEMS IMU, please contact us.

Tuesday, January 23, 2024

Application of Tilt Sensor in Vehicle Four-wheel Positioning

Article details: https://www.ericcointernational.com/application/application-of-tilt-sensor-in-vehicle-four-wheel-positioning.html

Tilt sensor in the four-wheel locator

For different four-wheel positioning equipment, the key role is to measure the accuracy of the tilt sensor. Modern cars generally adopt front and rear independent suspension, and the main parameters detected by the four-wheel alignment instrument are wheel camber, kingpin rear angle, kingpin internal angle and front bundle. For the measurement of the above tilt angles, except the front beam angle is generally realized by the rotary disk or the angle sensor, and the other angles are generally adopted by the tilt sensor. The tilt sensor is fixed on the four-wheel alignment mounting plate, and then installed on the wheel of the car through the clamp.

Due to the reason of automobile structure, the tilt measurement of automobile wheel positioning angle is divided into direct measurement and indirect measurement. From the definition of wheel inclination, it can be seen that the measurement of wheel camber can be measured directly by the tilt sensor, while the kingpin internal inclination and kingpin rear inclination are not, because the kingpin is installed on the inside of the wheel, generally can not be measured directly by the tilt sensor. The measurement range of wheel inclination should be about ±15°. In today’s models, the inclination adjustment deviation value is generally about 5′, such as: Shanghai Volkswagen PASSAT B5 front wheel camber value is -0°35′ to ±0°25′, so the sensor measurement resolution should be less than or equal to 5′.

What is car four-wheel positioning?

From the structure of the car, the car’s steering wheel (front wheel), steering knuckle and front axle installation between the three has a certain relative position, this installation with a certain relative position is called steering wheel positioning, also known as front wheel positioning. Front wheel positioning includes

Kingpin back tilt (angle), kingpin inward tilt (angle), front wheel outward tilt (angle) and front wheel front bundle four contents. For the two rear wheels, there is also a relative position between the installation and the rear axle, called the rear wheel positioning. Rear wheel positioning includes wheel roll out (angle) and one rear wheel front bundle. In this way, the front wheel positioning and the rear wheel positioning are called four-wheel positioning.

When the vehicle leaves the factory, the positioning angle is pre-set according to the design requirements. These positioning angles are used together to ensure the driving comfort and safety of the vehicle. However, because the vehicle is sold and driven for a period of time, these positioning angles will change due to traffic accidents, severe bumps caused by uneven road potholes (especially when driving at high speed suddenly encounter uneven roads), chassis parts wear, chassis parts replacement, tire replacement and other reasons. Once the positioning angle changes due to any reason, it may produce uncomfortable symptoms such as abnormal tire wear, vehicle deviation, reduced safety, increased fuel consumption, accelerated wear of parts, heavy direction, and vehicle drift. Some symptoms make the vehicle very dangerous at high speeds.

What is a four-wheel locator?

The purpose of four-wheel positioning maintenance service is to diagnose and treat the above causes of vehicle discomfort by measuring the positioning Angle. Generally, the new car should be four-wheel positioning after 3 months of driving, and every 10,000 kilometers after driving, replacing the tire or shock absorber, and after the collision should be timely four-wheel positioning. The correct positioning of the wheel can ensure that the steering is flexible, the seat is comfortable, the straight line driving is maintained, the life of the tire is extended, and the vibration caused by the road is reduced.

At present, most of the instruments used for wheel positioning detection are “four-wheel positioning instrument”. During the detection, the four-wheel positioning instrument first measures the current four-wheel positioning parameters of the car, and then the computer automatically compares it with the stored value of the corresponding model to calculate the deviation value of the four-wheel positioning of the car, and the maintenance personnel can restore the original state by correcting the prompts of the positioning instrument.

In Summary:

Ericco introduces the ER-TS-4256DI1, a tilt sensor for automotive four-wheel aligners, which has multiple interfaces and can be easily embedded into user systems. It can resist external electromagnetic interference, adapt to the harsh industrial environment for long-term work, is the ideal choice for industrial automation control and platform attitude measurement. The main features are as follows:

Biaxial dip measurement (X and Y)

Resolution less than 0.01°, accuracy 0.1°

Single PCB board, easy to embed into the user circuit system

Single power supply, digital signal (RS485) output

Built-in temperature sensor (digital SPI output)

Vibration resistance 3500g

MEMS Accelerometer Installation Error Correction Method

In order to further improve the accuracy of MEMS accelerometer, the measurement error of mems acceleration sensor must be reduced as much as possible. The measurement errors of it mainly include heating and noise errors, installation errors and non-orthogonal errors between axes. In order to such measurement errors, various errors must be compensated and corrected.

Methods for correction of heat and noise errors

When the MEMS accelerometer output is affected by heat and electronic noise, it can be said that the main influence of mems acceleration sensor output performance is heat and electronic noise. Electronic noise is usually a high frequency signal, so a low pass filter is added to the output of MEMS accelerometer to filter out the error caused by high frequency noise. After sampling and quantization, the filtered signal enters the DSP processor, and then performs digital filtering. The mean value of the quantization noise introduced is zero and has the characteristics of uniform probability density and white power spectral density. Therefore, it is assumed that the output of MEMS is affected by an additive white noise independent of the sampled signal and unbiased. So, by averaging multiple samples of MEMS output over a long enough period of time, the standard deviation of noise can be greatly reduced. After filtering and mathematical processing, the errors introduced by heat and electronic noise can be minimized.

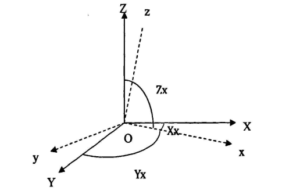

Installation error model

As shown in the figure, x, y and z axes are the coordinate system of MEMS acceleration sensor, and X, Y and Z axes are the measurement coordinate system. Due to the installation error of MEMS acceleration sensor during installation, there is a certain deviation between x, y and z axes of sensor coordinate system and the axis of measurement coordinate system. In order to change the performance of MEMS accelerometer and obtain accurate results, Therefore, the installation error should be compensated. Its mathematical model is as follows:

Taking the X-axis accelerometer as an example, when the sensor’s sensitive axis coincides with the X-axis of the measuring coordinate system:

Ax1=Ox+Sxx·Gx

In the above formula:

Ax—X axis accelerometer’s output;

Ox—X axis accelerometer’s zero position error;

Sxx—X axis accelerometer’s scale factor ;

Gx—X axis gravitational acceleration component in the direction;

Taking the X-axis accelerometer as an example, when the sensor’s sensitive axis does not completely coincide with the X-axis of the measuring coordinate system, the Y-axis and Z-axis components will be generated, then there are:

Ax2=Sxy·Gy+Sxz·Gz

In the above formula:

Gy—y axis component of gravitational acceleration along

Gz—z axis component of gravitational acceleration along

Sxy—y axis correction coefficient of the gravitational acceleration component along

Sxz—z axis correction coefficient of the gravitational acceleration component in the direction

When these two cases are taken into account, a mathematical model of the accelerometer’s X-axis can be obtained:

Ax=Ax1+Ax2=Ox+Sxx·Gx+Sxy·Gy+Sxz·Gz

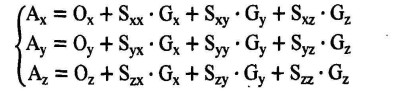

When extended to the case of three axes, the digital model of the three accelerometers on the probe is:

Among them:

Output of Ax,Ay,Az – x,y,z accelerometers;

Gx,Gy,Gz – the true gravitational acceleration component in the x,y,z direction;

Oi,Si – Each correction factor (12 in total)

The traditional 6-parameter correction method only considers the zero error and scale factor of each axis, and does not consider the error between each axis, that is, Syx=Sxy=Szx=Sxz=Szy=Syz=0. Since the installation of the acceleration sensor will inevitably generate installation errors, the non-orthogonal error between each axis is not considered. Therefore, the measurement error of the 6-parameter correction method without considering the non-orthogonal error between the axes is relatively large.

MEMS accelerometer installation error correction method

According to the established mathematical model of the installation error of MEMS acceleration sensor, there are two methods to calculate the 12 parameters in the formula. The first method is the special point method, which uses the special position of the measurement coordinate system to calculate and separate the coefficients O,S, and then the real acceleration component G of each axis can be obtained. This method has high accuracy requirements for the measurement equipment,so the correction costs are high; Another method is the automatic calibration method, which has the advantage of increasing the measurement accuracy without being affected by the environment and equipment accuracy. Its theoretical basis is: under static conditions, the output vector of the MEMS acceleration sensor is consistent with the acceleration of the earth’s gravity. In a short time, the value of each parameter can be calculated by nonlinear optimization.

Principle of special point correction method

The method of special point correction is to put the MEMS acceleration sensor to be corrected in some special position by using the calibration table with high precision, so as to eliminate the coefficients in the model and calculate the parameters in the model.

Summary

The installation error analysis and correction of MEMS accelerometer is one of the important links, which can improve the accuracy and accuracy of the accelerometer. Of course, the choice of mems accelerometer is also a key link, ericco launched ER-MA-5 in zero bias stability can reach 5 μg, but also has the characteristics of small volume and light weight. It is believed that mems accelerometers with good cost performance and correct error correction methods will provide more stable and reliable data support for applications in related fields.

The full text link: https://www.ericcointernational.com/application/mems-accelerometer-installation-error-correction-method.html

Email : info@ericcointernational.com

Whats app:+8613992884879

Why Is Gyro Steering Replacing Traditional Magnetic Steering in High-Stakes Projects?

Precise directional measurement is the core technology for ensuring the wellbore follows the planned trajectory, effectively avoiding adja...

-

For more information, please indicate in the “Ask for a Quote” box at the bottom of the page that you learned about this North Finder fr...

-

With the advantages of all-solid state, high performance and flexible design, fiber optic gyroscope has become the mainstream inertial...

-

Horizontal directional drilling technology completes the task of laying underground pipelines without destroying the surface environment....

.jpg)