Ericcogyro is a leader supplier of Inertial Sensor products North Finder,North seeking system,DTG,FOG,MEMS Gyroscope,Accelerometer,IMU,INS,electronic compass, our inertial sensor are sold worldwide and get the good feedback from our clients .

Wednesday, March 13, 2024

Tuesday, March 5, 2024

Soft Magnetic Error Compensation Method of Electronic Compass

1. Analysis of soft magnetic error of electronic compass

There is another ferromagnetic substance in the working environment of the electronic compass sensor, which, unlike hard ferromagnetic materials, is easily magnetized in a weak magnetic field. When the external magnetic field changes, its induced magnetism will also undergo a related change. The size and direction of the induced magnetic field will also change with the attitude and position of the carrier.

Because of its special properties, this material is called soft iron material. This soft iron material magnetizes itself due to the size of the external magnetic field it receives to produce a magnetic field that resists changes in magnetic flux, which can vary over a wide range. If the magnetic field in the space where the electronic compass sensor is located is known, the magnetic field actually measured by the electronic compass sensor is equal to the superposition of the geomagnetic field and the magnetic field generated by the soft iron interference. The soft iron error is equivalent to a time-varying error superimposed on the output of the electronic compass sensor. Because of the different properties of soft magnetic interference error and hard magnetic interference error, the least square method is no longer applicable when compensating soft magnetic interference error. Soft magnetic interference will lead to the deviation of the measurement Angle of the electronic compass. In an ideal environment, the Angle rotated by the measurement of the electronic compass is controllable, but the existence of soft magnetic interference error will lead to the deviation and uncontrollable Angle of the measurement process of the electronic compass. In the application of navigation system, a small Angle difference will lead to a large route error. The modern electronic compass has strong anti-interference and can suppress most of the Angle deviation, but the compensation of soft magnetic error is still worth studying and discussing.

2. Soft magnetic interference error compensation method

In the actual use of electronic compass, the noise errors caused by soft magnetic interference are mostly random noise errors. At present, there are many algorithms that can be used to compensate random noise and most of them are relatively mature, but considering the characteristics of electronic compass requiring real-time and rapid processing of large amounts of data. Three very mature random noise compensation algorithms, namely Kalman filter, improved Sage adaptive Kalman filter and particle filter, are selected as soft magnetic interference compensation algorithms. These three algorithms are easy to implement and can handle dense data.

2.1 Kalman filter

Kalman filtering algorithm can estimate the linear system with Gaussian white noise, which is the most widely used filtering method at present, and has been well applied in the fields of communication, navigation, guidance and control. The basic idea is that the minimum mean square error criterion is the best estimation criterion, and the future state quantity of the system is estimated by recursion theory, so that the estimated value is as close as possible to the real value.

2.2 Adaptive Kalman filtering

Traditional Kalman filter requires that the mean of dynamic noise and observed noise of the system be zero, and the statistical characteristics are known white noise, but these conditions may not be satisfied in practice, so there are modeling errors. Due to the limitation of objective conditions such as computing tools, the filtering algorithm is easy to produce error accumulation when running on the computer. This results in the loss of positivity or symmetry of error covariance matrix and the instability of numerical calculation.

2.3 Particle filter algorithm

The particle filter algorithm originated from the research of Poor Man's Monte Carlo problem in the 1950s, but the first applied particle filter algorithm was proposed by Gordon et al in 1993. The particle filter is based on the Monte Carlo method, which uses sets of particles to represent probabilities and can be used for any form of state-space model. Particle filter can accurately express the posterior probability distribution based on the observed and controlled quantities, and is a sequential important sampling method. Bayesian inference and importance sampling are the basis of understanding particle filtering.

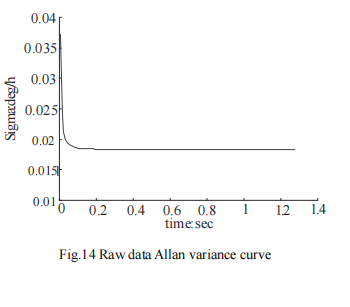

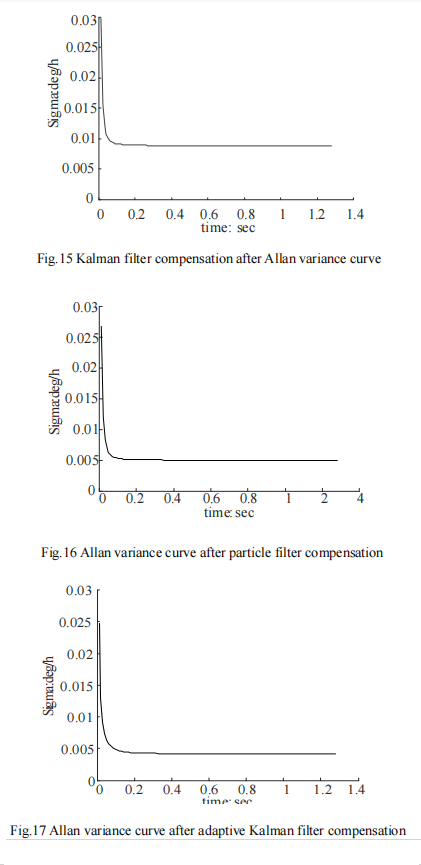

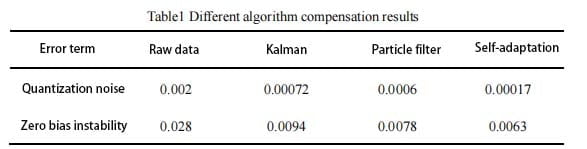

3.Allan variance simulation experiment

The Allan analysis of variance is used to simulate the original data of random sequence, the data compensated by Kalman filter algorithm, the data compensated by particle filter algorithm, and the four groups of data compensated by adaptive Kalman filter algorithm. Verify the feasibility of Allan variance analysis algorithm. The Allan standard deviation curve of each data is drawn according to the analysis results. The Allan standard deviation curves of the four groups of data are shown in FIG. 14-17 respectively.

4. Summary

From FIG. 14 to FIG. 17, it can be seen that the Allan variance program of the paper can effectively analyze the experimental data.

Several sets of experimental data show that the program is effective.

After analyzing the data before and after compensation, it can be seen that the quantization noise and zero bias instability noise of the data after compensation by Kalman filter algorithm are reduced by 64% and 66.4% respectively. The quantization noise and zero bias instability noise of the compensated particle filter data are reduced by 70% and 72.1% respectively. The quantization noise and zero bias instability noise of the data compensated by adaptive Kalman filter are reduced by 91.5% and 75.7% respectively. All the algorithms we mentioned can have a better compensation effect for the original data noise.

It can be seen from the compensation effect that compared with traditional Kalman filter and particle filter, adaptive Kalman filter can better remove the noise in the original data, and filter the noise of ER-EC-385, ER-EC-365B and other types of electronic compass. The random data in the simulation experiment is based on the simulation of the noise caused by soft magnetic interference. The simulation results show that the filtering algorithm can compensate the noise of soft magnetic interference.

Sunday, March 3, 2024

Magnetic Sensitivity of FOG IMU

Inertial measurement unit (IMU) is the key of position and attitude system to obtain high-precision position and attitude information and realize high-precision airborne Earth observation. IMU with high-precision fiber optic gyro (FOG IMU) is sensitive to magnetic field due to Faraday effect of fiber coil, and the performance parameters of FOG zero bias and drift are deteriorated, thus the performance of IMU decreases. For FOG without taking any measures, its zero bias sensitivity is 104 (°)/(h·T), which can meet the requirements of general low-precision inertial measurement systems, but typical high-precision inertial navigation systems (such as POS) require FOG zero bias sensitivity of 1 ~ 10 (°)/(h·T), because of this, to achieve high precision IMU with FOG (FOG IMU), some technical measures must be taken to reduce the magnetic sensitivity of FOG.

1. Methods to reduce magnetic sensitivity

In the development stage of FOG, the technical measures to reduce magnetic sensitivity are mainly depolarization technology and advanced loop winding technology. Single-mode fiber can achieve lower magnetic field sensitivity than the polarization-preserving FOG through depolarization technology. The polarization-preserving gyro can suppress zero drift well because of its large linear bifold beam relative to the circular bifold beam induced by magnetic field. However, the main axis of polarization-preserving optical fiber has slow rotation in the drawing process, and it will also lead to torsion when winding optical fiber coil. Therefore, the Faraday effect in polarization-maintaining fiber is not completely zero. Using advanced winding technology to reduce the residual torsion of the coil and effectively control the tensioning force during the winding process, it can improve the quality of the polarity-maintaining coil and reduce the magnetic sensitivity. In addition, multiple compensators can be configured in the FOG scheme, the combined magnetic sensitivity of the compensators can be used to eliminate the magnetic sensitivity of the coil, and the FOG magnetic sensitivity can be reduced by using a new type of optical fiber with less magnetic sensitivity.

At the application level, the technical measures to reduce FOG magnetic sensitivity are mainly compensation and magnetic shielding. Magnetic sensors (such as fluxgate, etc.) are used to determine the FOG’s magnetic error model in advance through calibration, and then compensation is carried out according to the model in application. However, it is necessary to arrange multiple sensors to fully understand the FOG’s magnetic field condition and add hardware circuits, which makes the system more complicated and affects its reliability. In order to isolate the magnetic field interference in the application environment, the shield with double or multi-layer shield structure is usually designed with μ-alloy material to achieve the maximum attenuation of the external magnetic field, so that although it can achieve better shielding efficiency, it often makes the structure complex, cost and weight increase. In the actual airborne application environment, the IMU based on the high precision FOG will be subject to the complex electromagnetic interference generated by the airborne electronic equipment and the shadow of the geomagnetic field, which will seriously affect its operational precision in the actual work process, and it will also be subjected to the external electromagnetic environment in the calibration test. The shadow affects its test precision. In this paper, the magnetic field sensitivity of high precision optical fiber IMU is studied, the mechanism of FOG’s magnetic field sensitivity is studied, the shielding effect (SE) of the shield is studied with the help of finite element analysis software, and the shield structure is designed. Three FOGs in IMU were screened, and the effectiveness and practicability of the shielding were verified by experiments.

2. Influencing factors of fiber optic gyroscope drift

2.1 Mechanism of influence of magnetic field on FOG

When linearly polarized light passes through the medium along the direction of magnetization or the direction of applied magnetic field, the phenomenon of rotation of the polarization plane is called magneto-optical Faraday effect. In Sagnac ring fiber interferometer, when there is a longitudinal magnetic field parallel to the coil in the plane of the fiber coil, the phase error Δφ generated by two backward linearly polarized beams is twice the Faraday rotation Angle. In practical applications, because the direction and size of the geomagnetic field and the external interference magnetic field are different, and the fiber torsion is distributed along the fiber. In the process of operation, the random stress changes due to temperature variation and vibration and other factors, and can not maintain a constant value, so the phase error of Faraday effect is not a fixed output bias, but a drift of FOG. For the axial magnetic field perpendicular to the optical fiber coil, the theory of the Faraday effect is zero, but in fact, each turn of the optical fiber ring has a small inclination Angle relative to its sensitive axis, when there is an axial magnetic field, it will produce an axial Faraday effect, which makes the FOG show magnetic sensitivity and produce errors.

2.2 Influence of external environment on fog drift

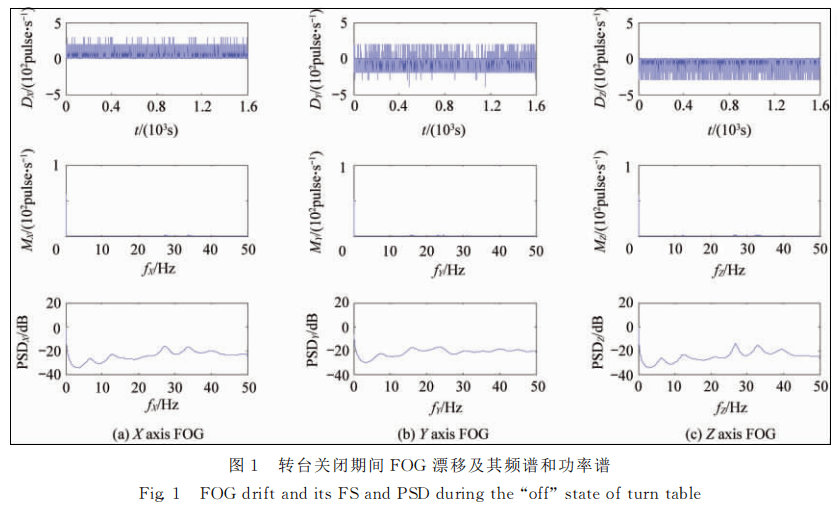

The IMU was installed on the three-axis turntable, and two sets of IMU output data were obtained at the sampling frequency of 100Hz respectively in the off state and the closed state of the turntable. Figure 1 shows the three FOG drifts (DX, DY and DZ, with a single bit of 102 pulse/s, that is, the number of output pulses of 0.01 s) and their spectra (FS, with a amplitude of MX, MY and MZ, with a single bit of 102 pulse/s, respectively) in IMU during turntable shutdown. Frequency classification is fX, fY and fZ, unit is Hz) and power spectrum (PSD, amplitude classification is PSDX, PSDY and PSDZ, single bit is dB). Figure 2 shows three FOG drifts and their frequency spectrum and power spectrum in the IMU during the closing period of the rotary table. The statistical results of FOG drift are shown in Table 1. When the turntable is closed, the FOG data contains frequency components distributed in the band width of 0 ~ 50 Hz. After the turntable is closed, the FOG drift is 5~10 times that of the original. Three main interference frequencies, 12.48Hz, 24.96Hz and 37.44Hz, are introduced.

3. Summary

We have to take corresponding technical measures to reduce the magnetic sensitivity of FOG, so as to improve the accuracy of FOG IMU.

Ericco’s ER-FIMU-50, ER-FIMU-60 and ER-FIMU-70 are all composed of fiber optic gyroscopes. In order to improve the accuracy of FOG IMU, we can completely reduce the magnetic sensitivity of the fiber optic gyroscopes inside (FOG IMU) them by corresponding technical measures.

Friday, March 1, 2024

Static Capacitance Test of MEMS Tilt Sensor

1. Performance test content

The main indicators of the MEMS tilt sensor sensor chip include static capacitance, static performance test and dynamic performance test. The static performance test includes measurement range, sensitivity, linearity, transverse sensitivity and zero stability. The dynamic performance test is mainly the bandwidth test.

1.1 Static capacitance test

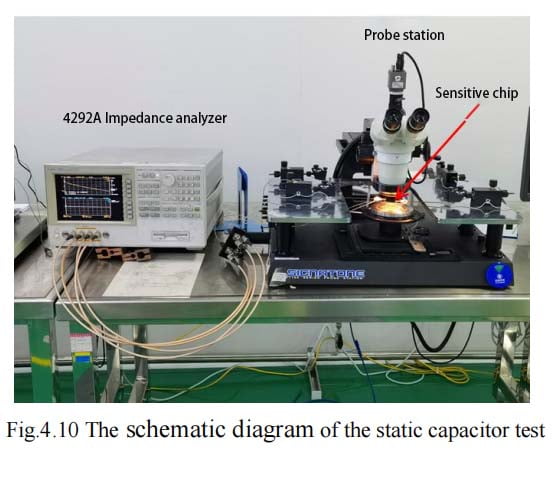

The static capacitance test was performed using wafer probe bench and Agilent 4294A impedance analyzer, as shown in Figure 4.10, mainly for screening MEMS tilt sensor sensitive chips before packaging.

The specific steps of static capacitance test are as follows:

(1) The sensitive chip prepared by the lead pad is placed on the table of the probe table in the 0g state;

(2) The measurement mode of the impedance analyzer is set as impedance-frequency test, the sweep frequency range is 2kHz~3kHz, and the excitation source voltage amplitude is 0.5V;

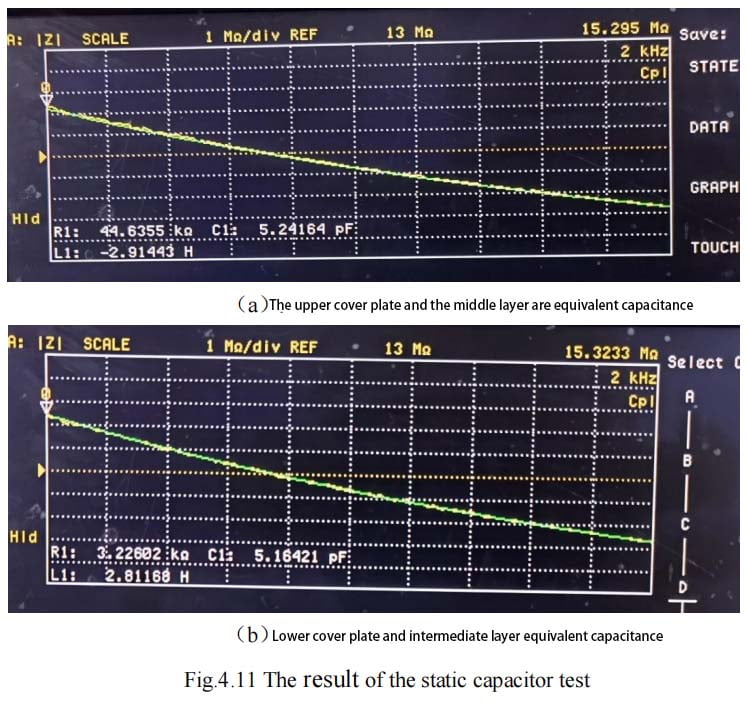

(3) Adjust the two probe bases, and contact the probe with the top cover pad and the middle sensitive structure layer pad respectively to obtain the impedance-frequency test curve, as shown in FIG. 4.11 (a), and obtain the equivalent capacitance by fitting;

(4) Adjust the two probe bases again, and contact the probe with the bottom cover plate of the sensitive chip and the welding pad of the middle sensitive structure layer respectively to obtain the impedance-frequency test curve, as shown in Figure 4.11 (b), and obtain the equivalent capacitance by fitting.

It can be seen from the test that the static capacitance of the middle sensitive structure layer and the upper and lower cover plate of the sensitive chip is 5.24pF and 5.16pF respectively, which has a good symmetry.

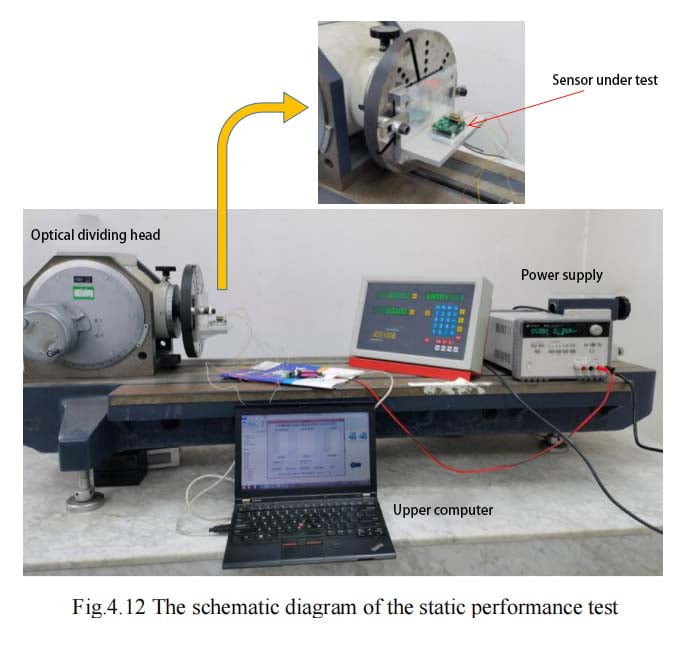

1.2 Static Performance testing

The static performance test of MEMS tilt sensor sensitive chip mainly includes range, sensitivity, linearity, lateral sensitivity and zero stability. The schematic diagram of static performance test is shown in Figure 4.12. Specific test methods and test results are as follows.

(1) Range, sensitivity, linearity test

① Test method

At room temperature in the laboratory, n Angle points are selected at basically equal intervals through the indexing head in the whole measurement range, corresponding to n acceleration value ai. Selection of + 90 ° range – 90 °, 75 °, 60 °, 45 °, 30 °, 15 °, 0 °, 15 °, 30 °, + + + 45 °, 60 ° +, + + 90 ° 75 °,; Plus or minus 30 ° range selection – 30 °, 25 ° ~ 20 °, 15 ° to 10 °, 5 °, 0 °, + 5 °, + 10 °, 15 ° + + 20 °, 25 °, 30 ° + +; ±15° Range selection -15°, -12.5°, -10°, -7.5°, -5°, -2.5°,

0°, +2.5°, +5°, +7.5°, +10°, +12.5°, +15°.

The input acceleration ai and the output value xi are linearly fitted using the least square method, and the fitting line is obtained as follows:

② Test procedure

a. Install the MEMS tilt sensor sensitive chip test board on the precision optical indexing head, ensure that the sensitive direction of the sensitive chip is perpendicular to the rotating shaft of the indexing head, connect the power supply and serial data acquisition line;

b. After the installation is complete, power the test board, stabilize for 10 minutes, and use 0° near the zero position of the sensitive chip

And 180° two-point method to determine the mechanical zero position of the sensitive chip.

c. According to JJF 1427-2013 “Micro-electromechanical (MEMS) line accelerometer calibration specification”, the range, sensitivity,

Linearity test.

③ Test results

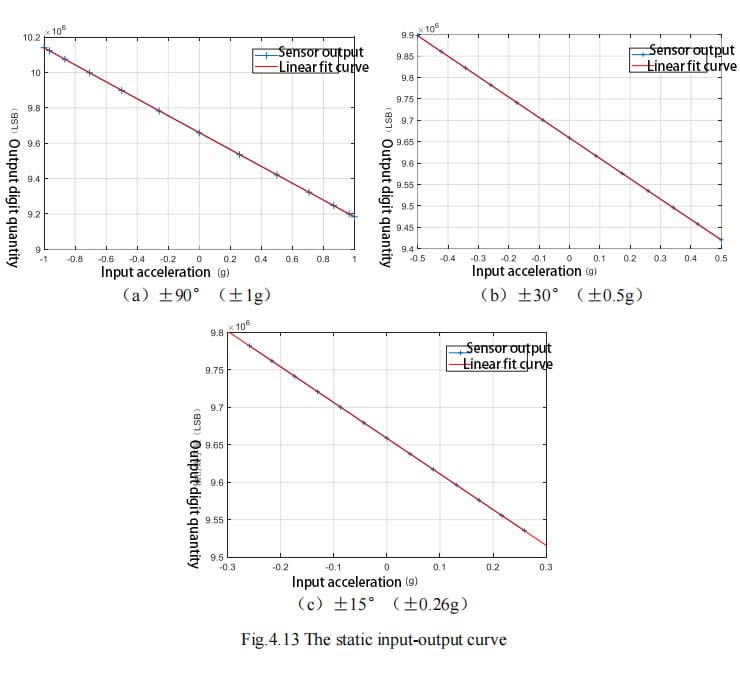

FIG. 4.13 (a) ~ (c) shows the sensitive characteristic curves of the MEMS tilt sensor sensor sensor in the range of ±90°, ±30° and ±15°, respectively. The linear fitting curves and residual errors are obtained by least square fitting of the curves, and the linearity results are obtained by equations (4.4) and (4.5). Detailed test results are shown in Appendix A, Schedule A.1~ Table A.3.

According to the static input and output curve of the sensor sensor chip, the sensitivity of the sensor sensor chip can be obtained as

477716LSB/g, since the corresponding capacitance range of the AD7745 is ±4pF in the 24-bit digital quantity variation range (16777216 LSB), it is calculated that the actual capacitance-acceleration sensitivity of the sensor sensor chip is about 0.228pF/g. In the range of ±90°, the linearity of acceleration is 0.19%FS, and the linearity of Angle is 0.22°. In the range of ±30°, the acceleration linearity is 0.11%FS and the Angle linearity is 0.06°. The acceleration linearity in the ±15° range is 0.06%FS and the angular linearity is 0.017°. These indexes can meet the requirements of conventional industrial inclination measurement.

(2) Lateral sensitivity test

① Test method

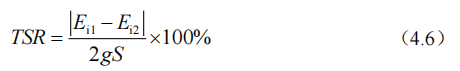

Put the sensor sensitive chip in the horizontal state, coincide with the rotation axis of the indexing head, rotate the indexing head in the clockwise (or counterclockwise) direction, take the equal Angle θ=30°, and test in 7 angular positions, that is, θi=0°, 30°, 60°,…… 180°, record the output value Ei1 at each position and the output value Ei2 at each position when the sensor sensor chip is flipped 180°. The lateral sensitivity of the sensor sensor chip can be obtained according to the formula (4.6).

Where, TSR is the cross sensitivity, S is the sensitivity, Ei1 is the output value at θi, Ei2 is the output value after flipping 180° relative to θi, and g is the acceleration of gravity. The maximum TSR calculated is the transverse sensitivity of the sensor sensor chip.

② Test procedure

a. Install the MEMS tilt sensor sensitive chip test board on the precision optical indexing head, ensure that the sensitive direction of the sensitive chip coincides with the rotation axis of the indexing head, and connect the power supply and serial data acquisition line;

b. After installation, supply power to the test board, stabilize for 10 minutes, and determine the mechanical zero position of the sensitive chip by using the 0° and 180° method near the installation zero position of the sensitive chip.

c. Perform lateral sensitivity test according to JJF 1427-2013 “Microelectromechanical (MEMS) Line accelerometer Calibration Specification”.

③ Test results

According to the above test methods and test steps, the lateral sensitivity of the MEMS tilt sensor sensor chip can be obtained

The degree is 5.2%FS, and the specific test data are shown in attached Table A.4. The index is still not ideal, the main reason is that the current package shell size is large, the sensitive chip mounting no reference, it is easy to lead to mounting deviation Angle, resulting in sensitive direction sensitivity of the sensitive chip leakage in the non-sensitive direction, which has a direct impact on the horizontal sensitivity index.

(3) Zero stability test

① Test method

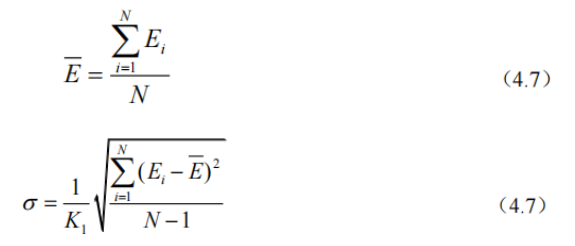

Set the sensitive direction of the sensor sensor chip to the horizontal state, coincide with the rotation axis of the indexing head, and record the output value of the prototype E1, E2, E3,…… EN, calculate the zero stability of the sensitive chip according to formulas (4.7) and (4.8).

Where, K1 is the sensitivity of the sensor sensitive chip, which is 477716LSB/g according to the previous test results, and σ is zero stability.

② Test procedure

a. Install the MEMS tilt sensor sensitive chip test board on the precision optical indexing head to ensure the sensitive chip

The sensitive direction is perpendicular to the rotating shaft of the indexing head, and the power supply and serial data acquisition line are connected.

b. After installation, supply power to the test board, stabilize for 10 minutes, and determine the mechanical zero position of the sensitive chip by using the 0° and 180° method near the installation zero position of the sensitive chip.

c. Conduct zero stability test according to JJF 1427-2013 “Micro-electromechanical (MEMS) Line Accelerometer Calibration Specification”, test time 1h.

③ Test results

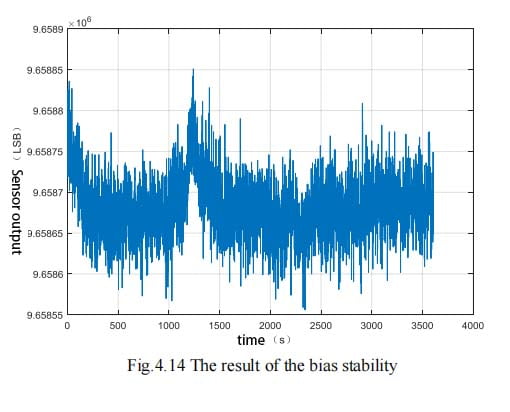

The test results of zero stability are shown in Figure 4.14

2. Summary

The calculation shows that the 1h zero stability of the sensor chip is about 81.3μg, which can meet the requirements of conventional industrial inclination measurement. Ericco’s ER-TS-3160VO and ER-TS-4158CU, which we have tested for static performance, have a high level of protection and can work in harsh industrial environments for a long time.

Adaptive method to detect vehicle motion status using MEMS-IMU

MEMS IMU refers to the inertial measurement unit (IMU) in microelectromechanical systems (MEMS). MEMS refers to high-tech devices with dimensions of a few millimeters or even smaller. Its internal structure is generally on the micron or even nanometer scale and is an independent intelligent system. MEMS IMU usually contains a gyroscope and accelerometer, which can be used to measure the angular velocity and acceleration of an object to determine the object’s motion state. Due to its small size, light weight, and low power consumption, MEMS IMU is widely used in navigation, positioning, attitude control and other fields.

MEMS IMU (microelectromechanical system inertial measurement unit) plays a vital role in detecting vehicle motion status. By integrating a MEMS IMU into a vehicle, various motion parameters of the vehicle, including acceleration, angular velocity, etc., can be monitored and measured in real time to determine the vehicle’s motion status.

Specifically, MEMS IMU can detect changes in vehicle acceleration and angular velocity. By analyzing these data, the driving status of the vehicle can be determined, such as whether it is accelerating, decelerating, turning, or braking. In addition, combined with other sensor data such as GPS, MEMS IMU can also provide more accurate positioning and navigation information, which is of great significance to the development of autonomous driving and intelligent transportation systems. The adaptive method of MEMS-IMU to detect vehicle motion status will be introduced in detail below.

The adaptive method of using MEMS-IMU to detect vehicle motion status mainly involves the following steps:

1.System integration and data acquisition: First, the MEMS-IMU (microelectromechanical system-inertial measurement unit) is integrated into the vehicle, usually placed in key locations, such as the vehicle chassis or tires, to capture the vehicle’s acceleration, angular velocity, etc. data. These data are transmitted in real time to subsequent processing units through the data acquisition system.

2.Data preprocessing: Since the original data may contain noise and outliers, data cleaning and filtering are required. Commonly used filtering algorithms include Kalman filters and complementary filters, which can remove noise and improve data quality.

3.Adaptive state detection: This is the core part, including the application of adaptive algorithms. Commonly used adaptive algorithms include, but are not limited to, adaptive filters, neural networks, and fuzzy logic systems. These algorithms can automatically adjust parameters based on dynamic changes in input data to better track and predict the vehicle’s motion status. For example, an adaptive filter can adjust its internal parameters based on previous data to better match current signal characteristics.

4.Motion state classification: Based on the processed data, use classification algorithms (such as support vector machines, decision trees or random forests) to classify the vehicle’s motion state. Common motion states include stationary, constant speed, acceleration, deceleration, turning, etc.

5.Feedback control: Based on the detected motion status, corresponding control strategies can be implemented. For example, in a self-driving vehicle, the vehicle’s steering and speed can be automatically adjusted when a turn is detected.

6.Real-time optimization and update: Since the vehicle’s motion state changes dynamically, the parameters of the adaptive algorithm need to be regularly updated and optimized to ensure continued accuracy and effectiveness.

7.System integration and testing: Finally, the entire adaptive detection system is integrated into the actual vehicle for testing to verify its performance and reliability. Make necessary adjustments and optimizations based on test results.

Summarize

Through the above method, MEMS-IMU can detect the motion status of the vehicle accurately in real time and provide important feedback information for vehicle control, autonomous driving and intelligent transportation systems. For example, ERICCO‘s ER-MIMU-08 can be applied to robot control and orientation in autonomous machines and unmanned vehicles, and can more accurately detect and measure motion states.

If you want to learn about or purchase MEMS IMU, please contact our relevant personnel.

MEMS IMU refers to the inertial measurement unit (IMU) in microelectromechanical systems (MEMS). MEMS refers to high-tech devices with dimensions of a few millimeters or even smaller. Its internal structure is generally on the micron or even nanometer scale and is an independent intelligent system. MEMS IMU usually contains a gyroscope and accelerometer, which can be used to measure the angular velocity and acceleration of an object to determine the object’s motion state. Due to its small size, light weight, and low power consumption, MEMS IMU is widely used in navigation, positioning, attitude control and other fields.

MEMS IMU (microelectromechanical system inertial measurement unit) plays a vital role in detecting vehicle motion status. By integrating a MEMS IMU into a vehicle, various motion parameters of the vehicle, including acceleration, angular velocity, etc., can be monitored and measured in real time to determine the vehicle’s motion status.

Specifically, MEMS IMU can detect changes in vehicle acceleration and angular velocity. By analyzing these data, the driving status of the vehicle can be determined, such as whether it is accelerating, decelerating, turning, or braking. In addition, combined with other sensor data such as GPS, MEMS IMU can also provide more accurate positioning and navigation information, which is of great significance to the development of autonomous driving and intelligent transportation systems. The adaptive method of MEMS-IMU to detect vehicle motion status will be introduced in detail below.

The adaptive method of using MEMS-IMU to detect vehicle motion status mainly involves the following steps:

1.System integration and data acquisition: First, the MEMS-IMU (microelectromechanical system-inertial measurement unit) is integrated into the vehicle, usually placed in key locations, such as the vehicle chassis or tires, to capture the vehicle’s acceleration, angular velocity, etc. data. These data are transmitted in real time to subsequent processing units through the data acquisition system.

2.Data preprocessing: Since the original data may contain noise and outliers, data cleaning and filtering are required. Commonly used filtering algorithms include Kalman filters and complementary filters, which can remove noise and improve data quality.

3.Adaptive state detection: This is the core part, including the application of adaptive algorithms. Commonly used adaptive algorithms include, but are not limited to, adaptive filters, neural networks, and fuzzy logic systems. These algorithms can automatically adjust parameters based on dynamic changes in input data to better track and predict the vehicle’s motion status. For example, an adaptive filter can adjust its internal parameters based on previous data to better match current signal characteristics.

4.Motion state classification: Based on the processed data, use classification algorithms (such as support vector machines, decision trees or random forests) to classify the vehicle’s motion state. Common motion states include stationary, constant speed, acceleration, deceleration, turning, etc.

5.Feedback control: Based on the detected motion status, corresponding control strategies can be implemented. For example, in a self-driving vehicle, the vehicle’s steering and speed can be automatically adjusted when a turn is detected.

6.Real-time optimization and update: Since the vehicle’s motion state changes dynamically, the parameters of the adaptive algorithm need to be regularly updated and optimized to ensure continued accuracy and effectiveness.

7.System integration and testing: Finally, the entire adaptive detection system is integrated into the actual vehicle for testing to verify its performance and reliability. Make necessary adjustments and optimizations based on test results.

Summarize

Through the above method, MEMS-IMU can detect the motion status of the vehicle accurately in real time and provide important feedback information for vehicle control, autonomous driving and intelligent transportation systems. For example, ERICCO‘s ER-MIMU-08 can be applied to robot control and orientation in autonomous machines and unmanned vehicles, and can more accurately detect and measure motion states.

If you want to learn about or purchase MEMS IMU, please contact our relevant personnel.

Thursday, February 29, 2024

Application of Gyro-Theodolite Orientation in Mine Surveying

1.Characteristics and working principle of gyro-theodolite

The gyro theodolite uses the axial fixation and precession of the gyro motor when rotating at high speed, and cooperates with the rotation of the earth itself to determine the direction. Within the range of 75° north and south latitude on the earth, it can not be affected by terrain, weather, and geomagnetic field, and can quickly and accurately determine the direction of true north regardless of day or night. Due to its excellent system principles, high precision, and wide range of response capabilities, the gyro-theodolite plays an important role in mine surveying, providing assistance for large-scale measurements such as directional measurements, mine penetration measurements, and contact measurements.

The grade of underground conductors is usually distinguished based on the error in angle measurement. The basic control conductors are 7″ and 15″. When the gyro theodolite starts with a gyro orientation error within the range of plus or minus 7″, the orientation measurement method of attached wire or closed wire terminal is generally used. Sometimes the measurement method of starting edge orientation is also used, which is divided into one well and two wells. Orientation measurement of the downhole starting edge of the well.

Gyro theodolite can effectively reduce the consumption of manpower, material resources and financial resources in the past geometric measurement and orientation work, save time, reduce costs, improve production efficiency and corporate benefits, and because the gyro theodolite can cope with various weather and terrains, It improves the accuracy of directional measurement work under extremely harsh conditions and the measurement accuracy when working on underground planes. The gyro theodolite can carry out precise horizontal directional measurement underground, continuously improve the accuracy with the measurement of control wires, and at the same time check the errors in the measurement of control wires to complete the directional measurement of mines and the penetration of large projects.

2.Application of gyro-theodolite orientation in mine penetration measurement

In mine survey, it is often required that a certain tunnel is connected to another designated tunnel according to the design, which is often referred to as tunnel connection. Usually during penetration operations, multiple excavation tasks are carried out at the same time to improve operation efficiency. At the same time, in order to allow the excavation work to proceed smoothly and ensure that different work teams can accurately carry out the excavation according to the plan, measurements in the predetermined direction must be carried out, which is the through measurement. Through measurement is helpful to ensure the smooth progress of the work, speed up the construction progress, improve the working environment, and ensure that mining and excavation are carried out in the right direction. The penetration measurement usually has the following situations: excavation of two working faces in opposite directions, excavation of two working faces in the same direction, and excavation from one end of the tunnel to the other end. There are three situations of tunnel penetration: tunnel penetration within a mine, mutual penetration between multiple mines, and longitudinal penetration of mine shafts.

The operation steps of gyro theodolite in mine penetration measurement are generally divided into 6 steps:

1) Investigate the hydrogeological conditions of the tunnels to be connected in advance, and select a scientific and systematic measurement method based on the actual situation;

2) Carry out simulation and calculation according to the selected measurement plan;

3) Study the feasibility of the plan based on the calculated results;

4) Determine the measurement plan, determine the geometric characteristics of the through-passage tunnel according to the relevant calculation results, and mark the geometric points of the tunnel on the design drawings and on site;

5) According to the needs of the tunnel connection work, promptly and regularly check various conditions of the tunnel, including the center line, waistline and other geometric elements of the tunnel, regularly check and measure and improve the drawings;

6) After the tunnel penetration work is completed, it is necessary to conduct on-site measurements with a gyro-theodolite in a timely manner, calculate the deviation between the actual penetration results and the measurement, analyze and evaluate the accuracy of the measurement work, and summarize the measurement experience.

The following uses specific engineering examples to introduce the application of gyro-theodolite in mine surveying. A certain mine adopts the freezing method for construction. In order to speed up the construction of the mine, the main tunnel, auxiliary tunnel, and wind shaft tunnel must be constructed through the tunnel, so penetration measurement must be carried out. Conduct a unified inspection of the geometric parameters of the ground control points to determine the geometric characteristics of the measured ground control points; conduct plane and triangular elevation measurements of the air shaft tunnels that pass through the main lanes, and use ground control point arrangements of 5″ and 7″ for the main lanes and auxiliary lanes. The traverse conducts trigonometric elevation measurements. Determine the general parameters of the instrument at a known position on the measuring ground. The gyro theodolite performs a total of 4 measurements, 2 measurements above the well and 2 measurements downhole. The mutual error between all measurement results must be less than 40″. The measurement in the downhole has 1 edge that requires directional measurement. By installing the gyro theodolite on At a fixed position, measure the falling azimuth of the directional edge, and then calculate the geographical azimuth of the directional edge to be measured. Multiple measurements must be made to ensure that the error is less than 25″ to meet the requirements. The azimuth and coordinate angle of each measurement point are already known on the ground. Now we need to calculate the directional edge underground based on the measurement and calculate the coordinate azimuth angle of the corresponding coordinate point. To find the coordinate azimuth angle, you must first find the meridian convergence angle. The geographical azimuth angle is the sum of the coordinate azimuth angle and the meridian convergence angle. The meridian convergence angle is positive or negative. It is positive to the east of the meridian and negative to the west. In the specific measurement, it should be calculated based on the formula of Gaussian coordinates and longitude and latitude of the location where the gyro-theodolite is placed.

3.Application of gyro-theodolite orientation in mine contact measurement

3.1 Casting points

In actual mine measurements, a spring steel wire with a diameter of about 1.5mm is used to drop points from the wellhead downwards. In order to reduce the error during the point throwing process, all fans must be turned off first, stop ventilating the inside of the mine, and use a barrier to Items such as wind boards reduce the impact of wind on the results of point casting. Then put a signal ring down every once in a while to see if the signal ring can fall completely. You can also ask professionals to ride on the equipment to check whether the wire suspension is free and vertical. Place a large bucket filled with stabilizing fluid in the horizontal direction, and the spring After hanging an object of a certain weight on the steel wire, it is sunk into the stabilizing liquid, and then multiple gyro-theodolite are used to perform swing observations in the vertical direction to determine the stabilized position of the spring steel wire.

3.2 Joint testing

When setting the point, it is required to jointly measure the spring steel wire both above and below the mine. Set up a gyro theodolite at the coordinate point on the ground, install a reflector on the wire, and then measure the GK point according to the 5″ wire, still based on the measurement above and below the mine. During the two centering measurements, the measured error must comply with the relevant mine measurement specifications. A gyro theodolite should also be set up underground, and the measurement and spring steel wire joint measurement should be carried out according to the 7″ wire.

4 Factors affecting the directional measurement accuracy of gyro-theodolite

In the measurement work of gyro theodolite, the pendulum orientation accuracy is usually determined by the error in one orientation. Generally speaking, the error in one orientation should be determined during the production process of the gyro theodolite and comply with the specification standards. However, in actual situations, the quality of gyro-theodolite varies and is easily affected by many aspects, including the manufacturer’s manufacturing level, usage environment, daily maintenance, etc. When using reversal point tracking for directional measurement, centering errors, side line mean errors, etc. can easily affect the measurement accuracy.

Summarize

To sum up, in the process of my country’s economic development, for large-scale mine construction projects, errors should be predicted based on the actual conditions of the project, and then directional measurements should be carried out in combination with advanced scientific measurement plans and methods. In mine surveying work, the gyro theodolite is the most widely used measuring instrument. It can adapt to day and night, different latitudes and terrain conditions, ensuring the accuracy of measurement results to the greatest extent. It is of great significance to the development of mine surveying work and mining engineering. Significance. Gyroscopic theodolite from Ericco. For example, ER-GT-02 can achieve more accurate measurements in mine measurements. The orientation accuracy of ER-GT-02 is ≤3.6″ (1σ); it has strong pit interference capability, integrated body design, compact structure, and stable performance; It has functions such as low position locking, automatic zero adjustment and observation.

If you want to learn about or purchase a gyro-theodolite, please contact us.

Wednesday, February 28, 2024

Measurement Error and Calibration of FOG IMU

1. What causes FOG IMU measurement errors?

Inertial measurement unit is the core component of navigation information and heading attitude reference system, which determines the accuracy and environmental adaptability of the system. Fiber optic gyro is a kind of photoelectric inertial sensor based on Sagnac effect. It has the advantages of high precision, strong resistance to vibration and shock, fast start, etc. It is an ideal angular velocity sensor for rotorcraft, high performance navigation information and heading attitude measurement system. FOG’s adaptability to temperature environment is poor, and the dynamic temperature environment in the working process of rotorcraft is harsh, which leads to the measurement error of FOG IMU. It is necessary to study the precise calibration compensation method of FOG IMU error to improve its environmental adaptability and measurement accuracy.

2. Calibration method

Traditional IMU calibration methods include static multi-position calibration under normal temperature environment, angular rate calibration and hybrid calibration, etc. Among them, static multi-position calibration method can calibrate the error coefficient of IMU acceleration channel with high precision, but due to the small Earth rotation rate, The precision of the small FOG used in the high performance navigation information and heading attitude measurement system of the rotorcraft is similar to the earth rotation rate, resulting in low calibration accuracy of the error coefficient of the angular velocity channel. The error coefficient of FOG IMU angular velocity channel can be accurately calibrated by the traditional simple angular velocity calibration method, but the error coefficient of acceleration channel cannot be accurately calibrated. How to further reduce the calibration workload and improve the calibration accuracy is the key technology to be solved by FOG IMU. In addition, parameters calibrated at room temperature will reduce FOG IMU measurement accuracy if applied at high or low temperatures. Methods such as least squares fitting are often used to compensate the zero-bias or scale-factor temperature errors of inertial devices. Among them, the high-order least squares fitting compensation method can improve the system accuracy, but significantly increase the calculation amount of real-time compensation. The one-time fitting method has a small calculation amount, but it cannot meet the actual compensation accuracy requirements. Therefore, it is another key problem for FOG IMU, a high performance and reliable navigation information and heading attitude measurement system of rotorcraft, to study the compensation method with small amount of computation and high precision.

Based on the FOG IMU integrated error modeling in the high performance navigation information and heading attitude measurement system of rotorcraft, we calibrate and compensate the temperature and dynamic errors of the small low-precision FOG IMU system, and propose a FOG IMU full temperature tripartite positive and negative rate/position calibration method and piecewise linear interpolation compensation method for temperature errors. A tripartite positive and negative speed/one position calibration scheme is designed at each constant temperature point, and piecewise linear interpolation method is used to compensate the zero deviation of angular velocity channel, zero deviation of acceleration channel and scale factor temperature errors. The vehicle-mounted experiments show that the method can improve the system’s environmental adaptability and measurement precision significantly, which lays a foundation for the further development of a small and high-performance fiber optic gyro IMU aircraft navigation information and heading attitude reference system.

3.FOG IMU deterministic error modeling

3.1 Angular velocity channel error model

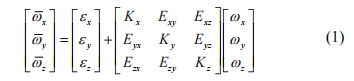

FOG IMU in rotorcraft, high performance navigation information and heading attitude measurement system consists of three fiber optic gyroscopes and accelerometers, IMU structure and data acquisition and preprocessing module. Three domestic small low-precision 11-FA fiber optic gyroscope sensitive carrier external input angular velocity, three GJ-27 quartz flexible accelerometers sensitive carrier external linear acceleration. FOG is insensitive to g and g2 terms. Considering the installation error, scale factor error and zero bias error of FOG IMU, the angular velocity channel error model of FOG IMU in northeast sky coordinate system is established as

Where, i is the output angular velocity of FOG IMU i axial gyro, and i is the input angular velocity of i axial gyro. i is zero deviation of i axis gyroscope; Ki is the scale factor of i axial gyroscope; Eij is the installation error coefficient of the angular velocity channel, and i and j are collectively referred to as the coordinate axes X, Y and Z.

3.2 Acceleration channel error model

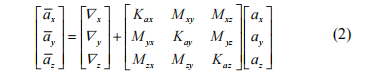

FOG IMU acceleration channel error model is:

Where, ai is the output of FOG IMU i axial addition, ai is the input of i axial addition, i is zero deviation of i axial addition, Kai is the scale factor of i axial addition, Mij is the installation error coefficient of acceleration channel.

3.3 Full temperature tripartite positive/negative speed/one position calibration

The precision of inertial devices in FOG IMU is mainly related to external environment mechanics and temperature excitation. The operating environment temperature of rotorcraft varies greatly with the different seasons and flight altitudes. Due to the large random dynamic disturbance caused by wind gust and turbulence during successive flights, the influence of different temperatures and dynamic environment on FOG IMU accuracy is mainly studied. The calibration temperature range, temperature point distribution density and calibration dynamic range are set according to the actual working environment and accuracy requirements of the system.

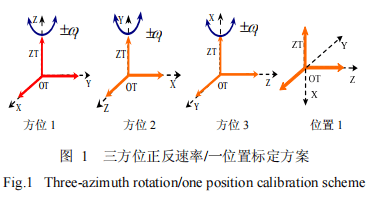

According to the mathematical model of system error, a FOG IMU tripartite positive and negative rate/one position error calibration method is designed based on a temperature-controlled single-axis speed turntable without pointing north and a high-precision hexahedron tool. As shown in Figure 1, the hexahedron tooling is turned three times at each calibrated temperature point to ensure that the X, Y, and Z axes of FOG IMU and the ZT axis of the turntable are reconnected respectively. According to the dynamic environment of the system, set the turntable in each direction to calibrate the positive and negative speed, and ensure that the rotation is above 360° at the speed point.

4. Full temperature piecewise linear interpolation compensation

In order to solve the problem of using FOG IMU in the navigation information and heading attitude measurement system of rotorcraft with high performance and small amount of computation and high precision error compensation, we use the segmented low-order linear interpolation method, dividing the interpolation interval into several cells, and using linear interpolation polynomial on each cell. It can be seen that the FOG IMU angular velocity channel and acceleration channel zero bias, scale factor temperature error piecework linear interpolation compensation algorithm of rotor aircraft operating environment are between -10℃ and 40℃, so the calibration temperature points are set as -10℃, 5℃, 20℃, 30℃ and 40℃ respectively. The FOG IMU is installed in the center of the hexahedron tool, and the X, Y and Z axes of the inertial navigation system are respectively parallel to the datum normal of the hexahedron tool through the high-precision positioning table. Then the hexahedral tooling is fixed horizontally on the plane of the temperature controlled single-axis rate turntable. The three-bit positive and negative speed/one-position calibration as shown in Figure 1 was realized by flipping the hexahedron tooling. Then change the temperature setting value, according to the above method, carry out the calibration experiment at -10℃, 5℃, 20℃, 30 ℃, 40 ℃ in turn.

5. Summary

FOG IMU is the core component of the navigation information and heading attitude reference system of small rotorcraft. ericco’s ER-FIMU-50 and ER-FIMU-70, we can use full-temperature three-way positive and negative rate/one position calibration and PLI compensation method. According to the error characteristics of fiber optic gyro and quartz flexible accelerometer, the FOG IMU error model is established, and the three-bit positive and negative rate/one-position calibration scheme is designed at each constant temperature point. The PLI algorithm is used to compensate the zero bias and scale factor temperature errors of the system in real time, reducing the calibration workload and the calculation amount of the compensation algorithm, and improving the system dynamics, temperature environment adaptability and measurement accuracy.

Why Is Gyro Steering Replacing Traditional Magnetic Steering in High-Stakes Projects?

Precise directional measurement is the core technology for ensuring the wellbore follows the planned trajectory, effectively avoiding adja...

-

For more information, please indicate in the “Ask for a Quote” box at the bottom of the page that you learned about this North Finder fr...

-

Horizontal directional drilling technology completes the task of laying underground pipelines without destroying the surface environment....

-

With the advantages of all-solid state, high performance and flexible design, fiber optic gyroscope has become the mainstream inertial...

.jpg)