1. Basic knowledge of gyroscope

A gyroscope is a device that can sense direction and angular speed. The simplest type of gyroscope is based on a rotating wheel that is fixed to the frame - many people think of it as a children's toy. Even if the frame around the wheel rotates, angular momentum keeps the direction of the wheel the same.

With the development of flying machines (airplanes and rockets) in the 20th century, gyroscopes were no longer just toys. The reason for this is that flying vehicles have navigational requirements that ground vehicles or even ships do not. That is, they can rotate and move freely in all three dimensions. Therefore, the pilot needs to constantly know the direction of the vehicle on the three axes to control the aircraft.

Unmanned rockets and missiles have further requirements. These aircraft need to know their direction and position without the need for human pilots to monitor them. The solution is the Inertial Guidance System (IGS). IGS uses gyroscopes to sense direction and angular motion to continuously control the vehicle and calculate its distance from the starting point.

2. What is a fiber optic rate gyroscope?

Fiber optic rate gyroscope (FOG) is a high precision rotating sensor. They are used in navigation and guidance systems for aircraft, spacecraft, ships and other vehicles. They sense rotation by measuring the interference of laser light propagating within the fiber coil.

3. Advantages of fiber optic gyroscope

The first gyroscopes were mechanical - a motor-driven rotating rotor and various sensors to read angular speed and direction information and provide it to a human pilot or IGS. These mechanical gyroscopes are relatively large and heavy. Their performance can be affected by vibration and require frequent calibration.

The interferometric fiber optic rate gyroscope was developed to overcome the limitations of mechanical gyroscopes. They use fiber coils, coherent light sources, and photodetectors to sense rotation instead of mechanical rotors. This results in smaller, lighter and more accurate systems.

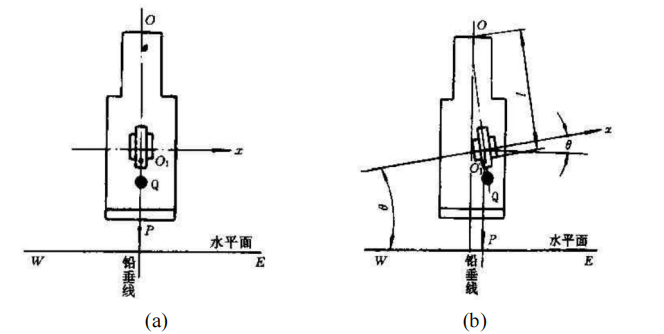

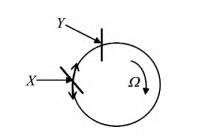

Inside the FOG, the light source is split into two beams before entering the fiber coil. Two beams of light are coupled to opposite ends of the fiber so that one beam travels in a clockwise direction and the other in a counterclockwise direction.

If the coil rotates about its axis, the two beams will undergo a phase shift relative to each other. This is called the Sagnac effect. When the two beams leave the fiber, they recombine. Any phase shift creates interference fringes in the combined beam. The detector senses this pattern to determine the angular speed of rotation. Typically, three coils (each mounted at right angles to the other two) are used to sense rotation on all three axes simultaneously.

But all of these different design forms have fairly similar requirements for the fiber optic coil at the center of the system. In particular, certain parameters are critical to the normal performance of the FOG. The most important are insertion loss, polarization extinction ratio (PER) and wavelength-dependent loss. Winding accuracy and packaging quality are also important.

To achieve good performance in these areas requires the ability to tightly control the manufacture of the fiber itself, as well as the process of winding it into a coil. In particular, the fiber coil must be wound in a perfectly symmetrical manner (so that a beam traveling in the opposite direction experiences the same conditions). In addition, it is also important to minimize the mechanical stress in the wound fiber.

4. FOG at work

FOG offers several significant advantages over conventional gyroscopes and even other non-mechanical technologies. For one thing, FOG is very sensitive and can detect very small rotational motions - angular velocities with a resolution of a few nanoradians per second. That's orders of magnitude better than a mechanical gyroscope. As a result, they provide more precise navigation and guidance.

In addition, FOG is relatively free from vibration and electromagnetic interference, and has a long service life and low maintenance requirements. This makes them useful in a variety of "harsh" environments or places where device access is limited. This includes spaceborne applications as well as inertial measurement systems for offshore and underwater vehicles and equipment.

Due to its high sensitivity and accuracy, FOG is also commonly used to stabilize fixed structures. For example, FOG can measure the rotating motion of structures such as Bridges, buildings, or antenna platforms and feed the data back to a control system that compensates for any movement. This helps to maintain the stability of the structure, especially in strong winds or earthquake conditions.

5. Summary

In short, the FOG is a high-precision and accurate rotation sensor with a wide range of applications. They are free from electromagnetic interference, relatively immune to vibration, have a long service life, low maintenance requirements, and are relatively small and lightweight. This makes them ideal for use in navigation, guidance and control systems for aircraft, ships and ground vehicles. In addition, they are useful in industrial automation and robotics.

Ericco's ER-FOG-851, ER-FOG-910 are two very popular fiber optic rate gyroscopes, with fast start, simple operation, easy to use and other characteristics, widely used in INS, IMU, positioning system, north finding system, platform stability and other fields. If you would like more technical data, please feel free to contact us.

.jpg)