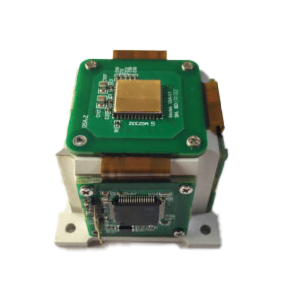

An inertial Measurement Unit (IMU) is a device that typically consists of a gyroscope for measuring angular rate and an accelerometer for measuring linear speed. In this article, we'll delve into the inner workings of an inertial measurement unit to explore all the relevant specifications and information you need to choose the right IMU for your application.

1. What is IMU?

An Inertial Measurement Unit (IMU) is a device that can measure and report the specific gravity and angular rate of an object to which it is attached. Imus typically include:

Gyro: provides angular rate measurement

Accelerometer: Provides specific force/acceleration measurement

Magnetometer (optional) : Measures the magnetic field around the system

Adding magnetometers and filtering algorithms to determine directional information results in a device called the Attitude and Heading Reference System (AHRS).

Imus are available in a variety of performance levels. According to the specifications of accelerometers and gyroscopes, they are divided into one of four categories:

Consumer/Automotive grade

Industrial grade

Tactical level

Marine class

These performance categories are often defined in terms of the sensor's operational bias stability, which plays such an important role in determining inertial navigation performance. The following table summarizes the various levels of performance for these specifications.

| Class | Cost | gyroscope operation bias stability | GNSS reject navigation time | applications |

| Consumer | < $10 | -- | -- | Smartphone |

| Industrial grade | 100$- 1000$ | <10°/h | <1 minute | UAV |

| Tactical level | $5,000- $50,000 | <1°/h | <10 minutes | smart ammunition |

| Navigation class | < $100,000 | <0.1°/h | a few hours | military |

Let's dive into the specific sensors used in IMUs, namely accelerometers and gyroscopes.

2. Accelerometers

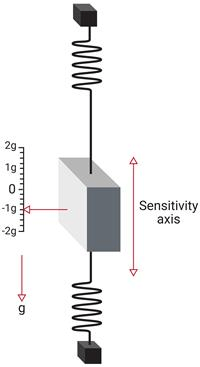

Accelerometers are the primary sensors responsible for measuring changes in inertial acceleration or velocity over time, and there are many different types, including mechanical accelerometers, quartz accelerometers, and MEMS accelerometers. MEMS accelerometers are essentially mass blocks suspended by springs, as shown in Figure 2. This mass block is called the test mass, and the direction in which the mass block is allowed to move is called the sensitivity axis. When the accelerometer is subjected to linear acceleration along the sensitivity axis, the acceleration causes the mass block to move sideways, and the amount of deflection is proportional to the acceleration.

3. Gyroscope

A gyroscope is an inertial sensor that measures the angular rate of an object with respect to an inertial reference frame. There are many different types of gyroscopes on the market with varying levels of performance, including mechanical gyroscopes, fiber optic gyroscopes (FOG), ring laser gyroscopes (RLG), and quartz /MEMS gyroscopes. Quartz and MEMS gyroscopes are typically used in the consumer, industrial, and tactical markets, while fiber optic gyroscopes cover all four performance categories. Ring laser gyroscopes typically have in-operation bias stability and range from 1°/ hour to less than 0.001°/ hour, covering tactical and navigation levels. Mechanical gyroscopes are the highest performing gyroscopes on the market with bias stability of less than 0.0001°/ hour in operation.

4. Magnetometer

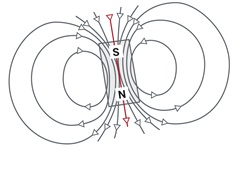

A magnetometer is a sensor that measures the strength and direction of a magnetic field. While there are many different types of magnetometers, most MEMS magnetometers rely on magnetoresistance to measure the surrounding magnetic field. Magnetoresistive magnetometers are composed of permalloy, and their resistance changes in response to changes in the magnetic field. Typically, MEMS magnetometers are used to measure a local magnetic field that is a combination of the Earth's magnetic field and any magnetic fields generated by nearby objects.

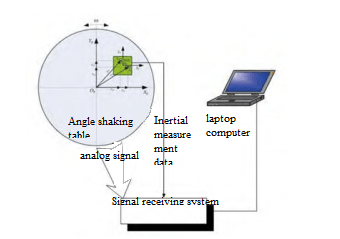

5. How does the Inertial Measurement Unit (IMU) work?

A single inertial sensor can only sense measurements along or around a single axis. To provide a three-dimensional solution, three separate inertial sensors must be mounted together to form an orthogonal cluster called a triplet. This set of inertial sensors installed in a triplet is often referred to as a triaxial inertial sensor because the sensor can provide a measurement along each of the three axes. Similarly, an inertial system consisting of a 3-axis accelerometer and a 3-axis gyroscope is called a 6-axis system because it provides two different measurements along each of the three axes for a total of six measurements.

The Inertial Measurement Unit (IMU) measures and reports the raw or filtered angular rate and specific force/acceleration experience of the object to which it is attached.

The data output of the IMU is typically body frame acceleration, angular rate, and (optionally) magnetic field measurements.

The user is then responsible for determining the pose by implementing an independent fusion algorithm, such as a Kalman filter.

6 Summary

Ericco's FOG Inertial Measurement Unit ER-FIMU-50, gyro bias stability is 0.5°-1°/h, ER-FIMU-60, gyro bias stability is 0.1°-0.5°/h, these two belong to the tactical class of fiber optic IMU. ER-FIMU-70 gyro bias stability is 0.05°-0.1°/h, it belongs to the navigation level of fiber optic inertial measurement unit, mainly used in the inertial navigation of surface-to-air missiles, air-to-air missiles and navigation missiles, space stability system, mapping system, attitude reference system and other fields.

.jpg)