The interferometric FOG gyro is a kind of angular velocity sensor based on Sagnac effect, which has the advantages of all-solid state, shock resistance, low cost, small size, etc., and has been widely used in aerospace, aviation, navigation, oil exploration well and other fields. Digital closed-loop IFOG carries out phase modulation according to the feedback signal, eliminates the phase shift caused by the speed, improves the dynamic range and scale factor linearity of IFOG, and is currently the mainstream scheme of medium-high precision IFOG. In the digital closed-loop fiber optic gyroscope, it is necessary to control according to the intrinsic frequency. The intrinsic frequency of different fiber optic gyroscopes is different, and the intrinsic frequency is usually generated by phase-locked loop technology. However, the system clock will have random fluctuations, and the frequency generated by the PLL will also fluctuate, which will lead to ripple interference in the output of the control system, and seriously affect the precision of the digital closed-loop fiber optic gyro.

In order to improve the reliability and adaptability of digital closed-loop IFOG, we established a theoretical model of digital closed-loop IFOG based on the principle of four-state square wave modulation and demodulation, analyzed the stable operating conditions and dynamic performance of digital closed-loop IFOG, and pointed out the shortcomings of the original IFOG digital closed-loop FOG gyro control system. An optimal control scheme of minimum beat without ripple is proposed. The performance of the digital closed-loop FOG gyro before and after optimization is compared by experiments. The results show that the zero bias stability and other performance indexes of the gyroscope after optimization are obviously improved.

1 Theoretical model

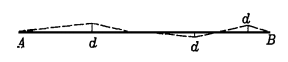

The digital closed-loop IFOG structure mainly includes light source, coupler, phase modulator (y-waveguide), optical fiber ring, photodetector, preamplifier, analog/digital converter (ADC), digital logic processor, digital/analog converter (DAC) and output buffer amplifier. The Sagnac interferometer consists of a light source, a coupler, a phase modulator and a fiber ring. When the fiber ring rotates, the phase difference generated by the two light waves traveling opposite each other in the loop is proportional to the rotation rate Ω.

2 Performance analysis and optimization

2.1 Control system performance analysis

The digital closed-loop IFOG frequency bandwidth increases with the increase of open-loop gain K, when the open-loop gain is greater than 0.2, in the high band, the gain is greater than 1. In order to obtain large bandwidth and stable control, 0.2 open loop gain is the best open loop gain.

2.2 Optimization of closed-loop control system

The performance analysis of the IFOG control system shows that the control system is a type I system with steady-state error under the input of angular acceleration. The sampler introduced in the design of integrator and step wave increases the overshoot and decreases the stability of the system. In order to improve the stability of the digital closed-loop FOG gyro, two samplers can be eliminated by output from the front stage of the cache during integral control and step wave generation. According to the control design method of second-order ripple free minimum beat system, the original IFOG controller is modified to eliminate the static error under the ramp input, and the optimized digital closed-loop IFOG ripple free minimum beat control system is obtained.

3. Experiment and result analysis

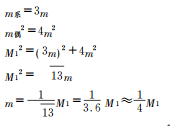

According to the block diagram of the digital closed-loop IFOG non-ripple minimum beat control system, the input-output relationship of the controller can be obtained as

Y (k) = y (k - 1) + [y (k - 1) - (k - 2)] y + x (k - 1) + [x (k - 1) - x (k - 2)], type: x (k) for k times the amount of error; y(k) is the output at time k. The above analysis shows that the output error and output can be delayed by two control cycles respectively through registers in FPGA, and the change of error and output can be obtained by subtracter and used for integral control, so as to realize the control of ripple free minimum beat system in FPGA.

According to the GJB2426A-2004 test method of FOG gyro, we evaluate the advantages and disadvantages of the non-ripple minimum beat control method by comparing the difference between the original control and non-ripple minimum beat control in the main indexes of FOG gyro, such as zero bias stability, Angle random walk and scale factor nonlinearity. The specific steps are as follows: the original control method and the non-ripple minimum beat control method are used to test the performance index of type 70 fiber optic gyro at room temperature respectively for 1 h. During the experiment, the length of the fiber ring in the fiber optic gyro is 800 m, the average diameter of the fiber ring is 70 mm, and the light source is the superradiation light-emitting diode. The optical wavelength is 1 310 nm, the ADC bit width is 12 bit, and the DAC bit width is 16 bit. The test results show that the output noise of the fiber optic gyro is obviously reduced under the control of the minimum beat without ripple, which indicates that the original control system results in a large output noise due to the influence of the control ripple. The analysis results show that the performance of fiber optic gyro is obviously improved under the control of non-ripple and minimum beat.

4 Summary

The theoretical model of IFOG digital closed loop under four-state square wave modulation is analyzed theoretically. It is pointed out that the original control system is a type I system, and the two-stage delay generated in the process of integral control and step wave generation reduces the reliability of the system, and the steady state error is proportional to the acceleration and inversely proportional to the open-loop control gain under the input of angular acceleration. In order to eliminate the influence of steady-state error, a digital closed-loop FOG gyro control system without ripple minimum beat is designed to eliminate the ripple error caused by the frequency of digital closed-loop IFOG in principle. The experimental results show that the ripple free minimum beat control can effectively improve the performance of digital closed-loop IFOG.

Ericco's ER-FOG-851, ER-FOG-910 stable performance, low power consumption, long life, is a very good choice, if you want to buy our fiber optic gyroscope, please feel free to contact us.

.jpg)