1. What causes FOG IMU measurement errors?

Inertial measurement unit is the core component of navigation information and heading attitude reference system, which determines the accuracy and environmental adaptability of the system. Fiber optic gyro is a kind of photoelectric inertial sensor based on Sagnac effect. It has the advantages of high precision, strong resistance to vibration and shock, fast start, etc. It is an ideal angular velocity sensor for rotorcraft, high performance navigation information and heading attitude measurement system. FOG's adaptability to temperature environment is poor, and the dynamic temperature environment in the working process of rotorcraft is harsh, which leads to the measurement error of FOG inertial measurement unit. It is necessary to study the precise calibration compensation method of FOG inertial measurement unit error to improve its environmental adaptability and measurement accuracy.

2. Calibration method

Traditional IMU calibration methods include static multi-position calibration under normal temperature environment, angular rate calibration and hybrid calibration, etc. Among them, static multi-position calibration method can calibrate the error coefficient of IMU acceleration channel with high precision, but due to the small Earth rotation rate, The precision of the small FOG used in the high performance navigation information and heading attitude measurement system of the rotorcraft is similar to the earth rotation rate, resulting in low calibration accuracy of the error coefficient of the angular velocity channel. The error coefficient of FOG IMU angular velocity channel can be accurately calibrated by the traditional simple angular velocity calibration method, but the error coefficient of acceleration channel cannot be accurately calibrated. How to further reduce the calibration workload and improve the calibration accuracy is the key technology to be solved by FOG inertial measurement unit. In addition, parameters calibrated at room temperature will reduce FOG inertial measurement unit measurement accuracy if applied at high or low temperatures. Methods such as least squares fitting are often used to compensate the zero-bias or scale-factor temperature errors of inertial devices. Among them, the high-order least squares fitting compensation method can improve the system accuracy, but significantly increase the calculation amount of real-time compensation. The one-time fitting method has a small calculation amount, but it cannot meet the actual compensation accuracy requirements. Therefore, it is another key problem for FOG inertial measurement unit, a high performance and reliable navigation information and heading attitude measurement system of rotorcraft, to study the compensation method with small amount of computation and high precision.

Based on the FOG inertial measurement unit integrated error modeling in the high performance navigation information and heading attitude measurement system of rotorcraft, we calibrate and compensate the temperature and dynamic errors of the small low-precision FOG inertial measurement unit system, and propose a FOG inertial measurement unit full temperature tripartite positive and negative rate/position calibration method and piecewise linear interpolation compensation method for temperature errors. A tripartite positive and negative speed/one position calibration scheme is designed at each constant temperature point, and piecewise linear interpolation method is used to compensate the zero deviation of angular velocity channel, zero deviation of acceleration channel and scale factor temperature errors. The vehicle-mounted experiments show that the method can improve the system's environmental adaptability and measurement precision significantly, which lays a foundation for the further development of a small and high-performance fiber optic gyro IMU aircraft navigation information and heading attitude reference system.

3.FOG IMU deterministic error modeling

3.1 Angular velocity channel error model

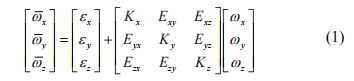

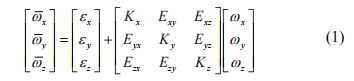

FOG inertial measurement unit in rotorcraft, high performance navigation information and heading attitude measurement system consists of three fiber optic gyroscopes and accelerometers, IMU structure and data acquisition and preprocessing module. Three domestic small low-precision 11-FA fiber optic gyroscope sensitive carrier external input angular velocity, three GJ-27 quartz flexible accelerometers sensitive carrier external linear acceleration. FOG is insensitive to g and g2 terms. Considering the installation error, scale factor error and zero bias error of FOG IMU, the angular velocity channel error model of FOG inertial measurement unit in northeast sky coordinate system is established as

Where, i is the output angular velocity of FOG inertial measurement unit i axial gyro, and i is the input angular velocity of i axial gyro. i is zero deviation of i axis gyroscope; Ki is the scale factor of i axial gyroscope; Eij is the installation error coefficient of the angular velocity channel, and i and j are collectively referred to as the coordinate axes X, Y and Z.

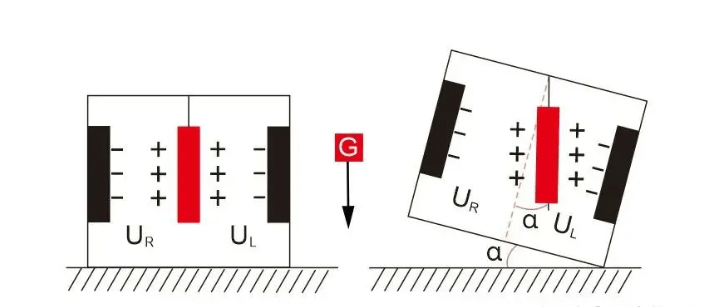

3.2 Acceleration channel error model

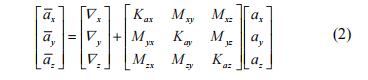

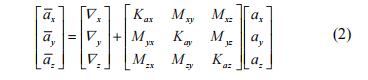

FOG IMU acceleration channel error model is:

Where, ai is the output of FOG inertial measurement unit i axial addition, ai is the input of i axial addition, i is zero deviation of i axial addition, Kai is the scale factor of i axial addition, Mij is the installation error coefficient of acceleration channel.

3.3 Full temperature tripartite positive/negative speed/one position calibration

The precision of inertial devices in FOG IMU is mainly related to external environment mechanics and temperature excitation. The operating environment temperature of rotorcraft varies greatly with the different seasons and flight altitudes. Due to the large random dynamic disturbance caused by wind gust and turbulence during successive flights, the influence of different temperatures and dynamic environment on FOG inertial measurement unit accuracy is mainly studied. The calibration temperature range, temperature point distribution density and calibration dynamic range are set according to the actual working environment and accuracy requirements of the system.

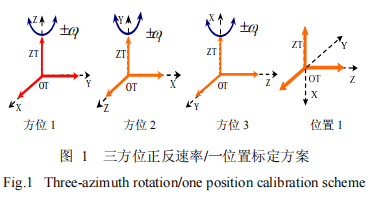

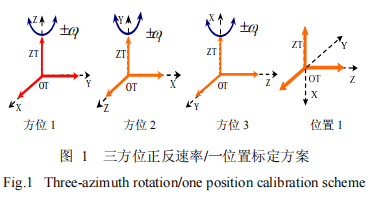

According to the mathematical model of system error, a FOG inertial measurement unit tripartite positive and negative rate/one position error calibration method is designed based on a temperature-controlled single-axis speed turntable without pointing north and a high-precision hexahedron tool. As shown in Figure 1, the hexahedron tooling is turned three times at each calibrated temperature point to ensure that the X, Y, and Z axes of FOG inertial measurement unit and the ZT axis of the turntable are reconnected respectively. According to the dynamic environment of the system, set the turntable in each direction to calibrate the positive and negative speed, and ensure that the rotation is above 360° at the speed point.

4. Full temperature piecewise linear interpolation compensation

In order to solve the problem of using FOG IMU in the navigation information and heading attitude measurement system of rotorcraft with high performance and small amount of computation and high precision error compensation, we use the segmented low-order linear interpolation method, dividing the interpolation interval into several cells, and using linear interpolation polynomial on each cell. It can be seen that the FOG inertial measurement unit angular velocity channel and acceleration channel zero bias, scale factor temperature error piecework linear interpolation compensation algorithm of rotor aircraft operating environment are between -10℃ and 40℃, so the calibration temperature points are set as -10℃, 5℃, 20℃, 30℃ and 40℃ respectively. The FOG inertial measurement unit is installed in the center of the hexahedron tool, and the X, Y and Z axes of the inertial navigation system are respectively parallel to the datum normal of the hexahedron tool through the high-precision positioning table. Then the hexahedral tooling is fixed horizontally on the plane of the temperature controlled single-axis rate turntable. The three-bit positive and negative speed/one-position calibration as shown in Figure 1 was realized by flipping the hexahedron tooling. Then change the temperature setting value, according to the above method, carry out the calibration experiment at -10℃, 5℃, 20℃, 30 ℃, 40 ℃ in turn.

5. Summary

FOG IMU is the core component of the navigation information and heading attitude reference system of small rotorcraft. ericco's ER-FIMU-50 and ER-FIMU-70, we can use full-temperature three-way positive and negative rate/one position calibration and PLI compensation method. According to the error characteristics of fiber optic gyro and quartz flexible accelerometer, the FOG inertial measurement unit error model is established, and the three-bit positive and negative rate/one-position calibration scheme is designed at each constant temperature point. The PLI algorithm is used to compensate the zero bias and scale factor temperature errors of the system in real time, reducing the calibration workload and the calculation amount of the compensation algorithm, and improving the system dynamics, temperature environment adaptability and measurement accuracy.

.jpg)