1. Influence of temperature on tilt sensor

Tilt sensor is widely used in various angle measurement, such as high precision laser instrument level, ship navigation attitude measurement, geological equipment tilt monitoring, satellite communication vehicle attitude detection. However, in the harsh working environment, the inclination sensor is easily affected by temperature, and there are zero point and sensitivity temperature drift.

Because the temperature of the working environment of the tilt sensor changes greatly, and the heat output caused by the temperature change will bring large measurement errors. At the same time, temperature changes also affect the size of zero and sensitivity values, and then affect the static characteristics of the sensor, so measures must be taken to reduce or eliminate the impact of temperature changes, that is, temperature compensation must be carried out.

2. Tilt sensor temperature compensation method

Inclination sensor temperature compensation methods are generally divided into hardware compensation method and software compensation method. Hardware compensation method is mainly achieved by changing device structure, material, working environment and technology to improve the reliability of measurement results. But in practical application, the working environment is bad, the structure of hardware compensation method is complicated and it is difficult to achieve the ideal effect. The idea of software compensation is to separate and compensate the error through experiment. Because the temperature error of tilt sensor is a nonlinear error, it is difficult to achieve a high compensation accuracy. RBF neural network has strong curve fitting ability. Compared with BP neural network, we use RBF neural network for temperature compensation of inclinometer sensor, which greatly reduces the influence of temperature on tilt sensor and achieves good compensation effect.

3. Temperature compensation based on radial basis function RBF neural network

3.1 RBF neural network compensation principle

RBF neural network is a kind of forward feedback-free network with excellent performance. It can approximate continuous function with arbitrary precision and has been widely used in pattern recognition, function approximation and so on. RBF neural network is composed of input layer, hidden layer and output layer. The hidden layer nodes are composed of Gaussian radial basis functions, as shown in equation (1) :

i=1,2,…,h (1)Where: ci is the center of the i-th basis function and has the same dimension as x; σi is the extension constant or width of the i-th basis function, and the smaller σi is, the smaller the width of the radial basis function and the more selective the basis function is. Neurons in the output layer adopt a linear activation function, and the output of the KTH neuron is shown in equation (2) :

Where: yk is the output of the KTH neuron in the output layer; W2ik is the connection weight of the I-th neuron in the hidden layer and the K-th neuron in the output layer.

In the parameter design of RBF neural network learning algorithm, it is generally necessary to design three parameters: data center of each basis function, expansion constant and weight of output node. We use K clustering algorithm to determine the basis function of the data center. Recursive least square method is used for the weight between hidden layer and output layer to ensure faster convergence speed.

3.2 RBF neural network temperature compensation results

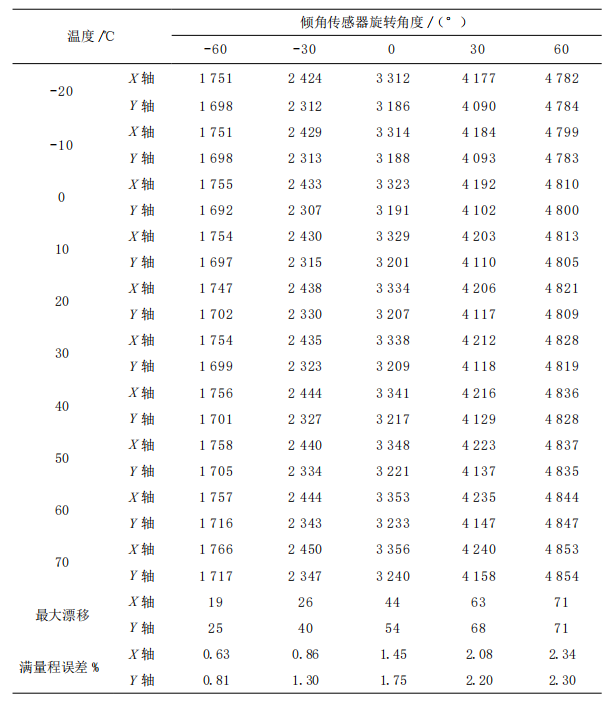

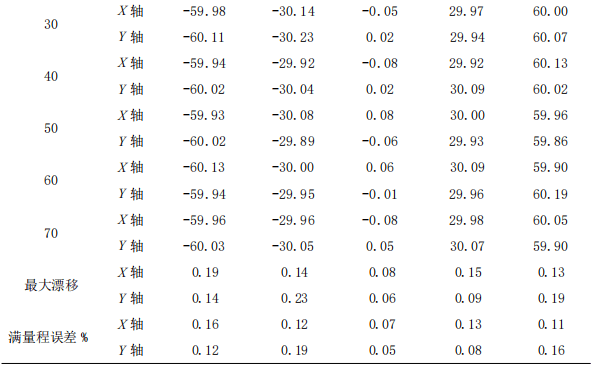

In the simulation experiment, the output value T1 of the inclination sensor and the temperature of the temperature box are taken as the input of the model, and the rotation Angle of the tilt sensor is taken as the output of the model. The 100 sets of data in the following table are samples of the RBF neural network two-input-output model.

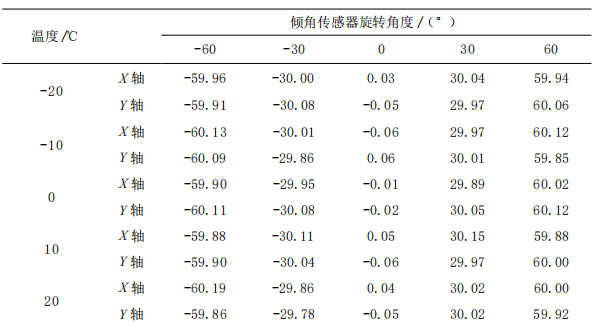

The input layer of the neural network is composed of two neurons, and the output layer is composed of one neuron. The number of hidden layer neurons is automatically added by the software through checking the output error until the error requirement or the maximum number of hidden layer neurons is reached. Through several experiments, the radial basis function distribution density SPREAD=0.5 and the training target error was set as EGOAL=1e-6. After 25 training sessions, the target training accuracy was achieved. Compensation results are shown in the following table.

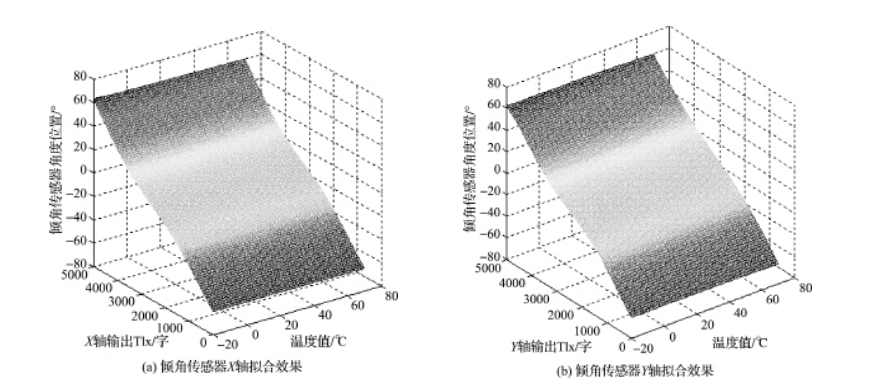

The output RBF neural network modeling graph is shown in the following figure

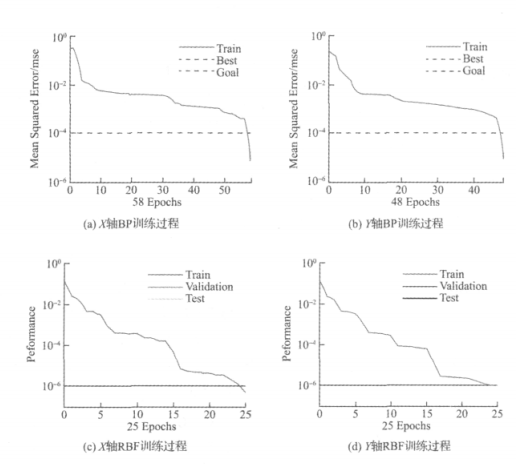

Comparing Table 1 and Table 2, it can be seen that the temperature drift and full scale error of each axis are greatly reduced after modeling by RBF neural network. As can be seen from the RBF network fitting effect diagram in FIG. 3, the simulation graphics transition smoothly at each point, and the model compensation effect is relatively ideal. In order to compare the compensation effect of the RBF network, we also set up the BP neural network compensation model which is often used for temperature compensation. The input layer of BP neural network is composed of two neurons and one implicit layer. After many experiments, it is determined that the optimal number of hidden layer is 5, and the output layer is composed of 1 neuron. The goal error of the training is EGOAL=1e^(-4), and the learning efficiency is LP.lr=0.2. In the experiment, 100 groups of samples in Table 1 were used to train the established BP network. After about 50 iterations, the training was completed. The training pairs of RBF and BP network were shown in the following figure.

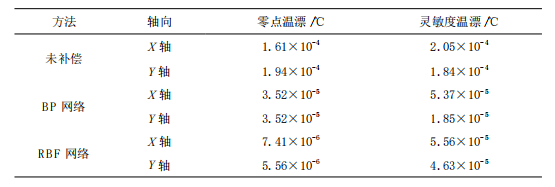

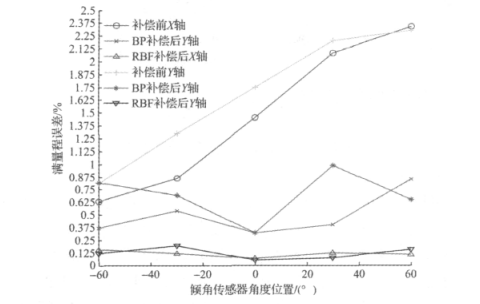

The target difference of BP neural network training is 1e^(-4), and that of RBF neural network training is 1e^(-6). However, the training time of RBF neural network is only about 1/2 of that of BP network, which shows that RBF convergence speed is relatively ideal. At the same time, the zero point temperature drift and sensitivity temperature drift before and after compensation are shown in following table. BP network and RBF network reduce the zero point and sensitivity temperature drift by 1 and 2 orders of magnitude respectively. The full scale error diagram of the inclination sensor under the action of -20~70℃ is shown in the figure below.

The maximum full scale error before compensation is about 2.34%, after BP neural network modeling compensation is about 0.85%, and after RBF modeling compensation is reduced to 0.158%. The simulation results show that the output error of the tilt sensor decreases after temperature compensation, and the output error decreases from 2.8° before compensation to 0.23° after conversion to angle degree. The modeling effect of RBF neural network is much better than that of BP network model, and it is very close to the actual expected value. Therefore, for the inclination sensor in this paper, RBF neural network modeling compensation can obtain better compensation effect.

Concluding discussion

We use RBF neural network compared with BP network to realize the research of temperature compensation of inclination sensor. The experimental results show that the RBF neural network modeling compensation achieves good compensation results in this system: for zero temperature drift, the X-axis decreases from 1.61×10^(-4) before compensation to 7.41×10^(-6), and the Y-axis decreases from 1.94×10^(-4) before compensation to 5.56×10^(-4). For sensitivity temperature drift, the X-axis decreased from 2.05×10^(-4) before compensation to 5.56×10^(-6), and the Y-axis decreased from 1.84×10^(-4) before compensation to 4.63×10^(-6). The RBF neural network is used to compensate the temperature of the inclinometer sensor, which reduces the influence of temperature on the sensor, overcomes the disadvantage that BP network is easy to fall into local optimal, improves the stability and measurement accuracy of the system, and lays a foundation for the application of the inclination sensor in various industries.

For example, Ericco’s ER-TS-12200-Modbus and ER-TS-32600-Modbus, both of which are dual-axis monitoring, we can completely carry out temperature compensation through RBF neural network modeling, and after compensation, the zero temperature drift and sensitivity temperature drift value of X axis and Y axis will be greatly reduced. In this way, we can reduce or even eliminate the adverse effects of temperature on the inclinometer sensor.

.jpg)

No comments:

Post a Comment