Quartz accelerometer is an important sensitive element in the strapdown inertial navigation system, which is used to detect the linear acceleration of the carrier. As a sensitive linear accelerometer, its internal structure design is not perfect, so many external factors have a great impact on the accuracy of the accelerometer. If the error compensation is not carried out, the error generated in the measurement process will have a great impact on the accuracy of the whole system. Among many environmental factors, the influence of temperature and vibration cannot be ignored, among which, the compensation of temperature error is relatively easy to realize and urgently needs to be solved.

Establishment of quartz accelerometer model

Quartz flexible accelerometer is a pendulum accelerometer in essence, the carrier is in constant motion, its linear motion and angular motion will affect the measurement accuracy of the pendulum accelerometer, is the main source of error. Under the condition of online movement, according to the basic principle of the accelerometer, the output value of the accelerometer and the specific force subjected to the pendulum can be described by mathematical expression, which is called the static mathematical model of the accelerometer, and in the process, the mathematical relationship between the generated measurement error value and the specific force subjected to the pendulum is called the static mathematical model of the accelerometer.

Pendulum components, signal sensors and torquers are the three most important components of pendulum accelerometers. The physical quantity that the accelerometer is sensitive to is the specific force. In order to measure the specific force accurately, a closed-loop system must be installed. The closed-loop system consists of a torque rebalancing loop.

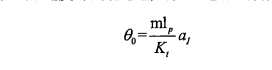

In an ideal state, the steady state output value of the accelerometer (current or Angle) is proportional to the input specific force, that is

Where m is the mass of the pendulum component, Lp is the distance that the center of mass of the pendulum component deviates from the output axis along the pendulum axis, Kt is the gain of the torque rebalancing loop, and aI is the specific force along the input axis.

Effect of temperature on quartz accelerometer

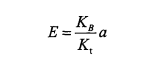

The output of the accelerometer used is the number of pulses, the output is proportional to the input acceleration, and the static equation can be written as

According to the static equation, the static accuracy of the accelerometer is mainly determined by the stability of the pendulum KB and the torque factor Kt. Torquer is an important part of the closed-loop feedback system of this kind of accelerometer. The power consumption of the torquer is proportional to the square of the voltage, and according to the formula, the power consumption is also proportional to the square of the input acceleration value, so the temperature change caused by the heating of the torquer itself will cause the instability of the scale factor. The table head is the main source of temperature error. From this we can see that the temperature coefficient of the scale factor of the torquer and the temperature change of the dial head determine the temperature error of the accelerometer.

When the accelerometer enters the stable working state, the temperature change of the meter head mainly comes from external and internal causes, and the external cause is the temperature change of the external working environment. The internal cause is that the torque coil works normally and heats up, and the heat generated indirectly affects the temperature of the meter head. When the quartz flexible accelerometer is in the working environment, from the power into the working state to adapt to the ambient temperature. During this period, the most important head temperature is unstable, and the output value of the quartz flexible accelerometer has a large deviation.

The balance element of the quartz flexible accelerometer is the permanent magnet torque coil, and the temperature change will affect the magnetic field, thus affecting the scale factor. However, temperature changes not only affect the magnetic field, but also the signal sensor, the elastic coefficient and the damping coefficient.

Static error model of quartz accelerometer

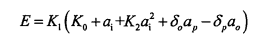

Static mathematical model equation of quartz flexible accelerometer

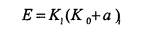

The further simplified model equation is

E is the output of the accelerometer, and the output unit is volt, milliampere, pulse number per second, etc.

K1is a scale factor, expressed in volts per gravity, milliamps per gravity, pulses per second per gravity;

K0 is the partial value, the unit is the acceleration of gravity;

K2is a second-order nonlinear coefficient;

Ai、ap and ao are the accelerations along the IA,PA and OA axes respectively, and the unit is the acceleration of gravity;

δo is the installation error of the input axis relative to the input reference axis IA around the output reference axis OA, in radians;

δp is the installation error of the input axis relative to the input reference axis IA around the output reference axis PA, expressed in radians.

Static temperature experiment and compensation method

The purpose of static temperature test is to measure the Ko and Ki values at different temperatures, and then compensate the error of offset value and scale factor by algorithm.

Test objectives: To determine the offset K0, scale factor K, second-order nonlinear coefficient K2, input shaft installation errors δo and δp of the accelerometer under different temperature conditions.

Test steps:

Step1: Place the quartz accelerometer on the temperature control turntable and connect the experimental equipment and instruments.

Step2: Start the quartz accelerometer and make it work on the temperature control turntable for more than 30 minutes. Set the temperature of the temperature control turntable to T=0℃, wait for the temperature inside the temperature control box to stabilize and hold for more than 30 minutes, and then start the test.

Step3: Rotate the turntable clockwise, make the measurement axis in order at 0°, 90°, 180°, 270° four positions, continue to measure the output value of multiple groups of quartz accelerometers, the test time at each position is 30 minutes.

Step4: Rotate the turntable clockwise to 360°, and then rotate the turntable counterclockwise to make its Angle at 270°, 180°, 90° and 0°, and continuously measure the output values of multiple groups of accelerometers. The test time was 30 minutes at each location.

Step5: Temperature control turntable increase the temperature △T=5℃, until the temperature in the temperature control box is stable and held for more than 30 minutes, repeat the third and fourth steps, and record the experimental data.

Summary

The static output of quartz accelerometer has very good repeatability. Under the condition of stable and repeatable output, the temperature error compensation model can be established to improve its accuracy. ERICCO’s quartz acceleration sensor series products are represented by ER-QA-01A, which has a bias repeatability of 10μg and a scale factor of 10 ppm. After long-term use, its accuracy can also be improved by temperature compensating. For different quartz acceleration sensor, the scale factor and offset value are unique, and the change amount and change situation are not the same, so the temperature compensation for different accelerometers should be tested and compensated separately.

the full text link:https://www.ericcointernational.com/application/temperature-error-analysis-of-quartz-accelerometer.html

Email : info@ericcointernational.com

Whats app:13992884879

.jpg)

No comments:

Post a Comment