The IMU (Inertial Measurement Unit) combines accelerometers, gyroscopes, and other sensors such as magnetometers to provide information on the direction, rotation, and motion of objects ranging from smartphones to spacecraft.

The two most common types of IMUs are built around microelectromechanical systems (MEMS) technology and fiber optic gyroscope (FOG) technology. Let's take a look at these two.

1. Fiber Optic Gyroscope (FOG) IMU

As the name suggests, FOG is a type of IMU that uses optical fibers to measure the angular speed or rotation rate of any object.

Due to the low noise of fiber optic gyroscopes, this technology has been widely used in demanding navigation applications.

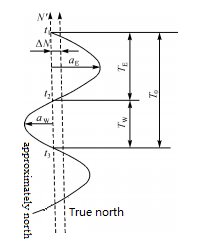

Fogs are inherently more accurate and stable than MEMS-based systems, which makes them preferred for scenarios where GNSS signals are not available (such as mining and underwater applications) or where GNSS rejection may occur. Another notable feature of FOG is its fast north finding capability. Even if the IMU itself is moving, the FOG IMU can measure the angular rotation of the Earth and achieve a heading in just a few minutes.

FOG gyro compasses have no moving parts, which makes them better able to withstand vibration and shock than MEMS gyro compasses. This means they are well suited for applications that may experience strong vibration levels, such as mining, defense, surface ships and aerospace.

2. Microelectromechanical System (MEMS) IMU

MEMS accelerometers detect linear acceleration and can then be used to calculate speed and distance. MEMS gyroscopes detect rotational motion and are typically used to determine heading and/or attitude (roll and pitch). When the data from the accelerometer and gyroscope are combined over time, the position of the object relative to its starting point can be calculated.

Due to their small size, mainstream manufacturing processes, common materials, and widespread adoption, MEMS IMUs are, on average, smaller, lighter, lower power, and more affordable than their FOG counterparts. However, because MEMS IMUs contain more micromechanical components and are more sensitive to temperature fluctuations, they tend to be less accurate and noisier than their fiber optic counterparts. If accurate location data is needed over an extended period of time, MEMS IMUs are often used in conjunction with GNSS receivers or other sensor technologies that provide supplementary location information.

MEMS IMUs are ideal for situations of low size, weight, power consumption and cost. Applications include mobile phones, vehicle navigation systems, autonomous ground vehicles, flying drones and robotic systems.

3. Here are the main differences between FOG IMU and MEMS IMU:

Technology:

FOG IMU uses a fiber optic gyroscope, using the principle of light interference in the fiber.

MEMS IMU uses MEMS systems with accelerometers and gyroscopes based on micromachining technology.

Working criteria:

FOG IMU measures motion by detecting the phase shift of light in the fiber coil due to rotation.

MEMS IMU utilizes the deflection of microstructure due to acceleration or rotation to measure motion.

Accuracy:

FOG IMU offers higher accuracy and precision than MEMS IMU. This makes them especially useful in cases where users rely on IMUs for long periods of time: accurate systems can calculate a location close to the real one even after a few hours.

Size and shape:

FOG IMUs are typically larger and heavier and are typically used in large systems such as aerospace and defense applications.

MEMS IMUs are smaller and more compact, making them suitable for integration into smaller devices such as consumer electronics.

Cost:

FOG IMU is more expensive due to its higher accuracy, highly specialized internal components, and sophisticated advanced manufacturing processes.

MEMS IMUs are generally more cost effective than FOG IMUs, making them widely used in consumer products.

Energy consumption:

FOG IMU consumes more power, which is less important in applications such as land vehicles and aircraft with readily available power supplies.

MEMS IMUs typically have low power consumption, making them suitable for portable and battery-powered devices.

Applications:

FOG IMU is commonly used in aerospace, defense, Marine navigation, and other high-precision applications, especially in situations where GNSS is not available or reliable, such as underground mining or military environments.

MEMS IMUs can be used in smartphones, gaming devices, drones, and a variety of consumer electronics that require motion sensing.

Robustness:

FOG IMU is more robust and stable, making it better suited for particularly harsh and demanding environments.

MEMS IMUs can be susceptible to environmental factors such as extreme temperatures and high vibration, which can affect their accuracy.

Calibration and automatic north finding:

FOG IMUs have better long-term stability and generally require less calibration frequency to maintain accurate heading or position. The most accurate fiber optic gyro systems are so sensitive that they can determine where north is by detecting the Earth's rotation.

Due to the potential for drift over time, MEMS IMUs may require more frequent calibration to maintain accuracy. They are not sensitive enough to automatically find the exact heading unless connected to a GNSS receiver.

Integration:

FOG IMUs are typically used in larger systems that can accommodate their size and weight and meet their higher power needs.

Due to their smaller size and lower power requirements, MEMS IMUs are easier to integrate into compact devices.

Summary

The choice between a MEMS-based IMU and a FOG-based IMU will depend on the customer's specific requirements for size, weight, power and cost (SWaP-C) as well as accuracy and stability needs.

For example, Ericco's FOG IMU ER-FIMU-50 is small in size, ER-FIMU-70 is high in precision, they have a very competitive price, very hot in the market, if you want to get more technical data, please feel free to contact us.

.jpg)