Introduce

The 12-point calibration is a method used for the calibration of the Inertial Measurement Unit (IMU). IMU is a device that can measure the acceleration and angular velocity of an object and is widely used in aerospace, navigation, robotics and other fields. In practical applications, the accuracy of IMU is crucial to the accuracy and reliability of measurement results. Therefore, it is essential to correct the IMU error through calibration.

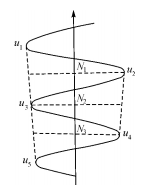

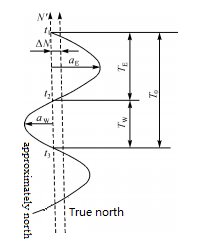

The 12-position method is a calibration method based on position changes. Its principle is to use mathematical models to calculate the error parameters of the IMU by recording the output data of the IMU at different positions and postures. Specific steps are as follows:

The first step is to determine the position: During the calibration process, a series of different positions and postures need to be selected. These positions should cover the entire measurement space as much as possible, and it is necessary to ensure that the output data of the IMU at these positions is reliable and accurate.

The second step is to collect data: At each position and attitude, fix the IMU on the object and collect the output data of the IMU. These data include accelerometer and gyroscope measurements. In order to improve the measurement accuracy, it is usually necessary to repeat the measurement multiple times and average it.

The third step is to establish a mathematical model: use the collected data to establish an IMU error model. This model can be solved through mathematical methods such as linear regression and least squares method. According to the parameters solved by the model, the output data of the IMU can be corrected.

The fourth step is to calculate the error parameters: According to the mathematical model, calculate the error parameters of the IMU. These parameters include zero bias, scale factor, non-orthogonality, etc. These parameters can be used to correct the output data of the IMU and improve the accuracy and precision of the measurement.

The fifth step is to verify the calibration results: The accuracy and reliability of the calibration results need to be verified. Some known accurate measurements can be used to compare the calibrated measurement results to ensure the validity of the calibration.

IMU calibration method using 12-position method

As a commonly used IMU calibration method, the 12-position method has the following advantages:

1.High accuracy: By performing calibration at different positions and postures, the error characteristics of the IMU can be more comprehensively considered and the accuracy and precision of the measurement can be improved.

2.Strong reliability: By repeating measurements multiple times and averaging, the impact of random errors can be reduced and the reliability of the calibration results can be improved.

3.Wide scope of application: The 12-position method is suitable for various types of IMUs, whether it is MEMS (Micro-Electro-Mechanical Systems) or fiber optic gyroscopes, etc.

4.Simple operation: The 12-position method does not require complex equipment and experimental conditions. It only needs to fix the IMU in different positions and postures for measurement.

However, the 12-position method also has some limitations:

1.It takes a long time: Since measurements need to be performed at multiple positions and postures, the calibration process is cumbersome and takes a long time.

2.High requirements for the test environment: Since the output of the IMU is affected by environmental factors, such as temperature, humidity, etc., the calibration process needs to be carried out in a well-controlled experimental environment.

Summarize

As a commonly used IMU calibration method, the 12-position method can effectively improve the accuracy and reliability of IMU measurement results. In practical applications, it is very important to select a suitable calibration method for IMU calibration based on specific needs and experimental conditions. Through calibration, the error of the IMU can be corrected and the accuracy of measurement can be improved to better meet the needs of practical applications. The MEMS IMU independently developed by Ericco has built-in gyroscopes and accelerometers. They have relatively high accuracy and can be used in many fields. For example, ER-MIMU-01 and ER-MIMU-05, welcome to learn more.

.jpg)