Nowadays, (Micro-electromechanical Systems, MEMS) inertial sensors and inertial systems have become an indispensable development direction of future navigation technology. MEMS technology has been widely used due to its advantages such as small size, light weight, low power consumption, low cost, and impact resistance. At present, the development of MEMS inertial technology is relatively mature. It forms a combined system with auxiliary systems such as gyroscopes and accelerometers, which can provide appropriate solutions for most navigation applications. The IMUs developed by Ericco are divided into MEMS IMU and FOG IMU. MEMS inertial measurement units are divided into tactical grade and navigation grade. Navigation-level IMUs can independently seek north, while tactical-level IMUs can rely on magnetometers or GNSS to find north. The following will be divided into two parts: an introduction to the working principle of the inertial measurement unit and a product introduction of ERICCO's tactical-level IMUs.

How the MEMS Inertial Measurement Unit (IMU) works:

The inertial measurement unit is a device that measures the three-axis attitude angle (or angular rate) and acceleration of an object. Generally, an IMU contains three single-axis accelerometers and three single-axis gyroscopes. The accelerometer detects the acceleration signals of the object in three independent axes of the carrier coordinate system, while the gyroscope detects the angular velocity signal of the carrier relative to the navigation coordinate system. Measure the angular velocity and acceleration of the object in three-dimensional space, and use this to calculate the attitude of the object. It has very important application value in navigation. IMUs are mostly used in equipment that require motion control, such as cars and robots. It is also used in situations where precise displacement calculations using attitude are required, such as inertial navigation equipment for submarines, aircraft, missiles and spacecraft.

The principle of an inertial measurement unit is very similar to taking small steps in the dark. In the dark, due to the error between your estimate of the step length and the actual distance traveled, as you take more and more steps, the difference between your estimated position and the actual position will become farther and farther. When taking the first step, the estimated position is relatively close to the actual position; but as the number of steps increases, the difference between the estimated position and the actual position becomes larger and larger. This method is extended to three dimensions, which is the principle of the inertial measurement unit.

The academic expression is: Based on Newton's laws of mechanics, by measuring the acceleration of the carrier in the inertial reference system, integrating it over time, and transforming it into the navigation coordinate system, the velocity in the navigation coordinate system can be obtained. , yaw angle and position information.

Therefore, in layman's terms, the inertial measurement unit IMU is a strapdown inertial navigation system. The system consists of three acceleration sensors and three angular velocity sensors (gyros). The accelerometer is used to feel the acceleration component relative to the vertical line of the ground. The speed sensor is used to get a feel for the angle information.

It is worth noting that the inertial measurement unit provides relative positioning information. Its function is to measure the movement route of the object relative to the starting point, so it cannot provide information about your specific location. Therefore, it is often combined with GPS. Used together, when the GPS signal is weak in certain places, the IMU can play its role, allowing the car to continue to obtain absolute position information and not get "lost."

ERICCO tactical grade inertial measurement unit

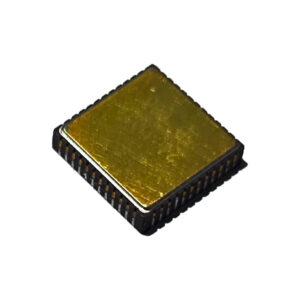

Next, we will mainly learn about a new inertial measurement unit - ERICCO INERTIAL SYSTEM tactical-grade inertial measurement unit: ER-MIMU03(High Precision Navigation/Stable Control MEMS IMU).

ERICCO launches a tactical-grade inertial measurement unit (IMU): ER-MIMU03 uses high-quality and reliable MEMS accelerometers and gyroscopes. Equipped with X, Y, Z three-axis precision gyroscope, X, Y, Z three-axis accelerometer, with high resolution, it can output the original hexadecimal complement of X, Y, Z three-axis gyroscope and accelerometer through RS422 code data (including gyroscope hexadecimal complement) numerical temperature, angle, accelerometer hexadecimal temperature, acceleration hexadecimal complement); it can also output gyroscope and accelerometer data that have been processed by underlying calculations Floating point dimensionless value. ). The IMU has a built-in acceleration sensor and gyroscope, which can measure linear acceleration and rotational angular velocity in three directions, and obtain the attitude, speed and displacement information of the carrier through analysis. Applications for this tactical-grade IMU include azimuth, attitude, position measurement and maintenance in GNSS-assisted INS. Heading, pitch, roll measurement in UAV AHRS Robot control and control Autonomous machines, unmanned vehicle directional stabilization and control satellite antenna pointing, target tracking system Guidance, navigation and control attitude and attitude IMU in tactical MEMS weapon systems The azimuth angle is maintained and positioned. Movement investigation and maintenance in MRU and other application areas.

High Precision Navigation/Stable Control MEMS IMU integrates a three-axis MEMS accelerometer and a three-axis MEMS gyroscope in a unique redundant design, which can maximize performance while reducing device size.

In terms of performance specifications, the High Precision Navigation/Stable Control MEMS IMU has an excellent gyroscope and accelerometer. The bias instability of the gyroscope is 0.3°/h. Enables long-term dead reckoning and maintains excellent heading performance. The MEMS sensor in ER-MIMU03 has extremely low vibration correction errors and can withstand high vibration environments up to 6.06g.

With very low gyro bias instability, the navigation performance of High Precision Navigation/Stable Control MEMS IMU can work well when GNSS is interfered with or has no signal. This tactical-grade IMU has relatively high accuracy compared to tactical-grade IMUs from other peer companies. If you want to purchase our IMU, please contact our relevant personnel.

.jpg)